News

Jan . 10, 2025 12:55 Back to list

fulvic and humic acid supplements factory

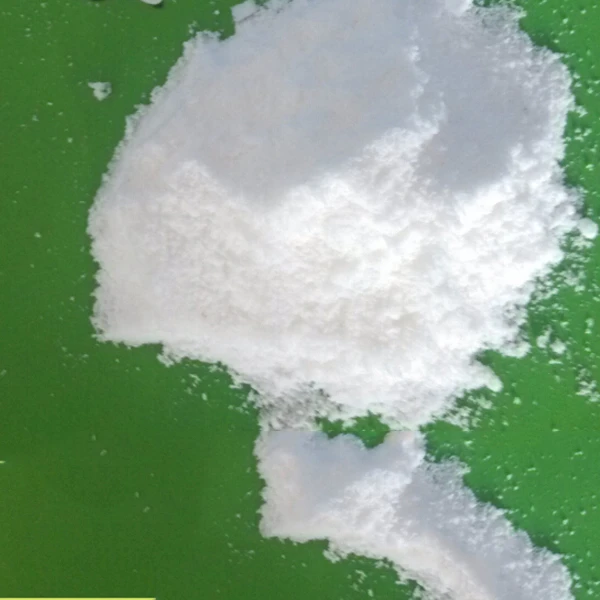

Polyaspartic acid, a remarkable polymer, has gained significant attention in the coatings industry due to its unique structure and versatile applications. Its chemical structure resembles that of naturally occurring aspartic acid, yet with synthetic modifications that enhance its properties. The backbone of polyaspartic acid comprises a polyamide linked via an amide bond, affording it extraordinary chemical stability and environmental resistance.

Polyaspartic coatings also stand out in terms of environmental responsibility. With growing awareness and regulations surrounding volatile organic compounds (VOCs), the market leans towards solutions that offer effective performance without ecological sacrifice. Polyaspartic systems typically exhibit low VOC content, aligning with international environmental standards and expectations. From a consumer perspective, the ease of application cannot be understated. Polyaspartic coatings allow for direct-to-surface applications, tooth-saving time and resources otherwise spent on extensive surface preparations. The consistency of the coating, a direct benefit of its molecular structure, results in fewer defects and a more uniform finish. For contractors, this translates to reduced labor costs and a faster project turnover, an advantage that directly impacts the bottom line. As more industries recognize the potential of polyaspartic acid structures, innovation continues to drive its adoption. Research and development efforts are focused on optimizing formulas that cater to specific industrial needs while maintaining the core benefits of fast curing, durability, and environmental resistance. In conclusion, the structure of polyaspartic acid is not merely a chemical curiosity but a cornerstone for developing advanced coatings that meet the rigorous demands of modern applications. Its contributions to efficiency, aesthetic longevity, and environmental safety establish it as a formidable contender in the specialty coatings arena. The stories of successful applications and satisfied end-users stand as a testament to its transformative impact across multiple industry sectors.

Polyaspartic coatings also stand out in terms of environmental responsibility. With growing awareness and regulations surrounding volatile organic compounds (VOCs), the market leans towards solutions that offer effective performance without ecological sacrifice. Polyaspartic systems typically exhibit low VOC content, aligning with international environmental standards and expectations. From a consumer perspective, the ease of application cannot be understated. Polyaspartic coatings allow for direct-to-surface applications, tooth-saving time and resources otherwise spent on extensive surface preparations. The consistency of the coating, a direct benefit of its molecular structure, results in fewer defects and a more uniform finish. For contractors, this translates to reduced labor costs and a faster project turnover, an advantage that directly impacts the bottom line. As more industries recognize the potential of polyaspartic acid structures, innovation continues to drive its adoption. Research and development efforts are focused on optimizing formulas that cater to specific industrial needs while maintaining the core benefits of fast curing, durability, and environmental resistance. In conclusion, the structure of polyaspartic acid is not merely a chemical curiosity but a cornerstone for developing advanced coatings that meet the rigorous demands of modern applications. Its contributions to efficiency, aesthetic longevity, and environmental safety establish it as a formidable contender in the specialty coatings arena. The stories of successful applications and satisfied end-users stand as a testament to its transformative impact across multiple industry sectors.

Latest news

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025