News

ديسمبر . 23, 2024 15:28 Back to list

Polyaspartic Acid Zinc Salt Manufacturer for Quality Coating Solutions

The Production and Applications of Polyaspartic Acid Zinc Salt

Polyaspartic acid zinc salt is emerging as a significant component in various industrial applications due to its unique properties. This compound is derived from polyaspartic acid and zinc, combining the beneficial aspects of both organic and inorganic materials. In understanding its production and applications, we can appreciate its growing importance in today's market.

Production Process

The manufacturing of polyaspartic acid zinc salt typically involves the reaction of polyaspartic acid with zinc salts. Polyaspartic acid itself is a biodegradable polymer derived from aspartic acid, an amino acid. The process begins by synthesizing polyaspartic acid through polymerization, where aspartic acid is converted into a long-chain polymer. This polymer exhibits several appealing characteristics, such as excellent adhesion, flexibility, and environmental resistance.

Once polyaspartic acid is synthesized, it is combined with a suitable zinc salt, often zinc sulfate or zinc oxide. The reaction conditions, including temperature and pH, are carefully controlled to ensure the formation of a stable zinc salt derivative. The resulting product exhibits the advantages of polyaspartic acid, along with the antimicrobial properties of zinc, making it ideal for various applications.

Key Properties

Polyaspartic acid zinc salt possesses several noteworthy properties. One of the most critical attributes is its biocompatibility and biodegradability, making it an environmentally friendly option compared to traditional synthetic polymers. Additionally, it exhibits excellent thermal stability and resistance to UV radiation, which enables its use in outdoor applications.

The presence of zinc in the formulation provides antimicrobial activity, making the compound suitable for applications that require hygiene and cleanliness. This property is particularly pertinent in the medical and food industries, where preventing microbial growth is essential.

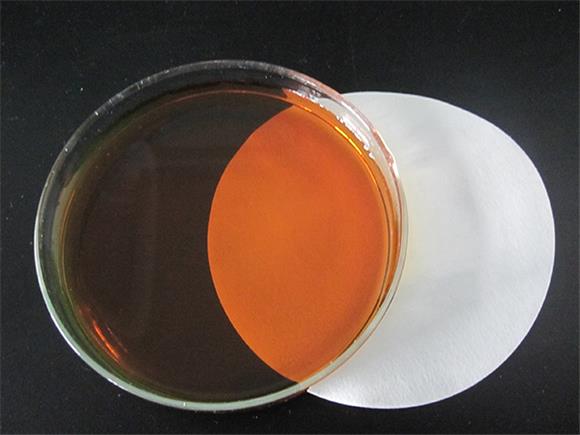

polyaspartic acid zinc salt factory

Applications

1. Coatings and Paints One of the primary applications of polyaspartic acid zinc salt is in the formulation of protective coatings and paints. These coatings are used in various sectors, including automotive, aerospace, and construction. The compound offers excellent adhesion to surfaces and enhances the durability of the coatings, providing long-lasting protection against environmental factors.

2. Water Treatment Due to its antimicrobial properties, polyaspartic acid zinc salt is utilized in water treatment processes. It helps in inhibiting the growth of bacteria and algae in water systems, ensuring cleaner and safer water. This application is critical in municipal water treatment plants and industrial water systems.

3. Agriculture In agriculture, polyaspartic acid zinc salt is used as a micronutrient supplement in fertilizers. Zinc is an essential nutrient for various crops, and its inclusion in fertilizer formulations can improve crop yield and quality. The slow-release properties of polyaspartic acid help in delivering zinc more efficiently to plants over time.

4. Biomedical Applications The biocompatibility of polyaspartic acid zinc salt makes it a candidate for various biomedical applications. It can be used in wound dressings and in drug delivery systems due to its ability to form hydrogels. These hydrogels can encapsulate therapeutic agents, allowing for controlled release and targeted treatment.

5. Construction Materials In the construction industry, polyaspartic acid zinc salt is incorporated into concrete and masonry products. It enhances the material’s durability and helps in preventing corrosion, especially in environments exposed to moisture and saltwater.

Conclusion

The polyaspartic acid zinc salt factory plays a pivotal role in the development and supply of this versatile compound. With a focus on sustainability and performance, the demand for polyaspartic acid zinc salt is likely to increase across various industries. As manufacturers continue to innovate and optimize the production process, we can expect to see even more applications arise, further solidifying its place in the market. Ultimately, the combination of environmental benefits and enhanced performance makes polyaspartic acid zinc salt a valuable material for the future.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025