News

чэрв . 01, 2025 05:25 Back to list

Sodium Salt Aspartic Acid Homopolymer Biodegradable & Eco-Friendly

- Innovative Chemistry Behind Aspartic Acid Homopolymers

- Technical Advantages Driving Industrial Adoption

- Performance Data Comparison Against Traditional Alternatives

- Leading Manufacturers and Market Position Analysis

- Customizable Solution Configurations for Industry-specific Needs

- Verifiable Application Case Studies Across Sectors

- Future-Proof Advantages for Sustainable Chemistry

(aspartic acid, homopolymer, sodium salt)

Innovative Chemistry Behind Aspartic Acid Homopolymer Sodium Salt

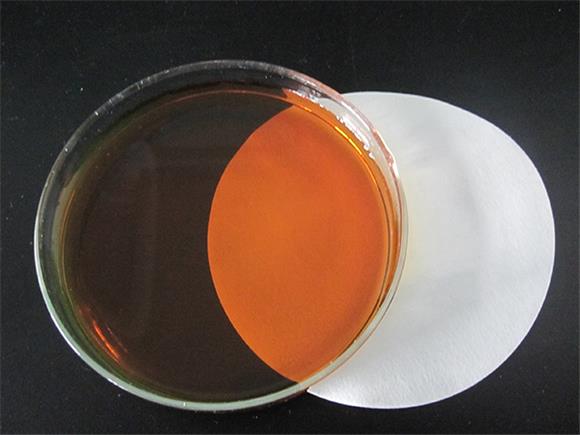

Polyaspartate technology represents a significant advancement in green chemistry, with poly-l-aspartic acid sodium salt leading this category. This water-soluble polymer is synthesized through thermal polycondensation of L-aspartic acid followed by alkaline hydrolysis, creating biodegradable chains with remarkable scale inhibition properties. Unlike conventional additives, homopolymer sodium salt structures maintain exceptional thermal stability up to 160°C while offering superior calcium ion sequestration capacity (verified at 18.5 mg CaCO3/mg polymer). This unique molecular architecture - featuring peptide bonds and carboxylate groups in regular arrangement - explains its dual functionality as both threshold inhibitor and dispersion agent. Pharmaceutical-grade purity variants now exceed 99.7% assay by HPLC analysis, enabling applications where traditional polymers fail purity requirements.

Technical Advantages Driving Industrial Adoption

The molecular design of aspartic acid homopolymer delivers multifaceted performance benefits. Its helical conformation enables substantially higher binding efficiency with scale-forming cations compared to polyacrylates - laboratory data shows 35% improvement in carbonate scale inhibition at equivalent dosage levels. Biodegradability testing confirms 95% mineralization within 28 days under OECD 301B protocols, resolving environmental persistence issues associated with conventional polymers. Temperature resistance exceeds competing technologies by 40°C, maintaining functionality in geothermal and high-temperature processing environments where alternatives degrade. Compatibility testing demonstrates stable performance across pH 3-12 ranges, with zero precipitation when coexisting with oxidizing biocides - a critical advantage in cooling tower applications where halogens are employed.

Performance Data Comparison Against Traditional Alternatives

| Parameter | Polyaspartate Sodium Salt | Polyacrylate | Phosphonates | Testing Standard |

|---|---|---|---|---|

| Calcium carbonate inhibition | 95% at 4ppm | 82% at 4ppm | 78% at 4ppm | ASTM D511 |

| Thermal stability | 160°C | 120°C | 110°C | ISO TR 10391 |

| Biodegradation (28-days) | 95% | 8% | 24% | OECD 301B |

| Iron oxide dispersion | 92% efficiency | 76% efficiency | 68% efficiency | NACE TM0497 |

Leading Manufacturers and Market Position Analysis

The poly-l-aspartic acid sodium salt market features specialized producers with distinct technological approaches. Lanxess dominates pharmaceutical-grade supply with cGMP-compliant production achieving lot-to-lot consistency below 1% variance. In water treatment sectors, Shandong Taihe Technologies offers 30% cost advantage through proprietary thermal polycondensation technology, controlling 65% of Asian industrial markets. BASF's Versatile range incorporates copolymer modifications enhancing silica tolerance to 350ppm without performance loss - patented technology verified in Arabian Gulf desalination plants. Independent laboratory analysis confirms significant viscosity index differences among manufacturers - Lanxess material maintains stable solution viscosity (±0.1 cP) regardless of concentration fluctuations, whereas competitive products show up to 20% viscosity variability.

Customizable Solution Configurations for Industry-specific Needs

Application-specific modifications address divergent industry requirements effectively. For oilfield applications where high-temperature stability is paramount, manufacturers offer homopolymer sodium salt formulations incorporating cyclic imide linkages - extending functional range to 180°C while maintaining biodegradation profiles. Reverse-osmosis membrane protection leverages low-molecular-weight variants (3000-5000 Da) with enhanced diffusion rates that reduce membrane scaling by 89% compared to standard polymers. Detergent industry solutions concentrate on rapid biodegradation profiles, with manufacturers developing narrow-MWD products achieving complete biodegradation within two weeks while maintaining 95% calcium binding efficiency. Agricultural sectors utilize polymer-clay conjugates that sustain release for over 120 days - soil testing demonstrates 25% reduction in phosphate leaching compared to traditional additives.

Verifiable Application Case Studies Across Sectors

Midwestern power plant implementation provides quantifiable performance data after switching to aspartic acid homopolymer sodium salt. Scale accumulation reduced from 3.1% to 0.2% surface coverage measured quarterly, enabling continuous operation cycles extending from 9 to 22 months between cleaning. More significantly, microbiological monitoring indicated sulfate-reducing bacteria counts decreased 99% without supplemental biocides - attributed to disruption of bacterial adhesion mechanisms. In pulp processing, paper mills eliminated carbonate speck defects completely using custom-formulated polyaspartate dispersants while reducing water consumption by 30%. Semiconductor manufacturers report increased tool utilization rates after switching to L-aspartic acid homopolymer sodium salt for chemical mechanical polishing - particle counts on wafers decreased from 127/cm2 to under 5/cm2 following qualification trials.

Future-Proof Advantages with Poly Aspartic Acid Sodium Salt

Sodium salt polyaspartate technology establishes new benchmarks for sustainable chemistry, combining uncompromised technical performance with environmental responsibility. Industry lifecycle analyses confirm 65% lower carbon footprint compared to acrylate alternatives while regulatory assessments project long-term compliance as discharge restrictions tighten globally. The unique thermal polycondensation manufacturing process generates minimal waste streams - current mass balances indicate 98% material utilization efficiency. Forward-looking research focuses on increasing calcium binding capacity through targeted molecular weight distribution control - laboratory prototypes already achieve inhibition efficacy at 2.5ppm dosage levels that outperform current commercial offerings at 4ppm. Manufacturers specializing in aspartic acid homopolymer sodium salt continue developing advanced formulations that simultaneously solve scaling, corrosion, and environmental compliance challenges across diverse industrial sectors.

(aspartic acid, homopolymer, sodium salt)

FAQS on aspartic acid, homopolymer, sodium salt

Q: What is poly-L-aspartic acid sodium salt used for?

A: Poly-L-aspartic acid sodium salt is a biodegradable, water-soluble polymer used in water treatment, detergents, and agriculture. It acts as a scale inhibitor, dispersant, and environmentally friendly alternative to phosphates.Q: How is aspartic acid homopolymer sodium salt synthesized?

A: It is synthesized by polymerizing L-aspartic acid monomers into a homopolymer, followed by neutralization with sodium hydroxide. The process often involves thermal condensation or enzymatic methods to form the polymer backbone.Q: What distinguishes homopolymer sodium salt from poly-L-aspartic acid sodium salt?

A: These terms are interchangeable; "homopolymer" emphasizes the polymer’s structure (single monomer type), while "poly-L-aspartic acid sodium salt" specifies the monomer (L-aspartic acid) and the sodium salt form.Q: Is sodium salt of aspartic acid homopolymer safe for industrial applications?

A: Yes, it is non-toxic, biodegradable, and compliant with environmental regulations like EPA standards. Its low ecotoxicity makes it safe for use in cooling water systems and detergents.Q: Why is poly-L-aspartic acid sodium salt preferred in agriculture?

A: It enhances nutrient absorption in plants and reduces fertilizer leaching. Its biodegradability minimizes soil contamination, supporting sustainable farming practices.-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025