News

снеж . 11, 2024 18:00 Back to list

Sodium Chelators and Their Role in CE Certification Processes for Safety and Compliance

Understanding CE Certification for Sodium Chelators

Sodium chelators play a significant role in various industrial processes, ranging from pharmaceuticals to agriculture. Their ability to bind metal ions and prevent unwanted reactions makes them valuable in formulating products that require stability and effectiveness. Given their widespread use, it is essential for manufacturers to understand the implications of CE certification specific to sodium chelators.

What is CE Certification?

CE marking is a certification that indicates a product's conformity with European health, safety, and environmental protection standards. It is mandatory for many products sold within the European Economic Area (EEA), including sodium chelators used in various applications. Achieving CE certification confirms that the product meets all the relevant European legislation, providing assurance to customers regarding quality and safety.

The Importance of CE Certification for Sodium Chelators

1. Market Access CE certification is often a prerequisite for entering the European market. For manufacturers of sodium chelators, obtaining this certification can be crucial for expanding their reach and enhancing their market competitiveness.

2. Consumer Confidence CE marking serves as a guarantee of safety and effectiveness. End-users, such as manufacturers of pharmaceuticals or agricultural products, are more likely to trust and prefer sodium chelators that are CE certified, knowing that they have undergone rigorous testing and evaluation.

3. Compliance with Regulations Various European directives and regulations govern the use of chemical substances in products. CE certification means that sodium chelators comply with these regulations, reducing the risk of legal issues and potential penalties for manufacturers.

The CE Certification Process

The process of obtaining CE certification involves several steps, which can vary depending on the specific product and its application. For sodium chelators, the following steps are generally required

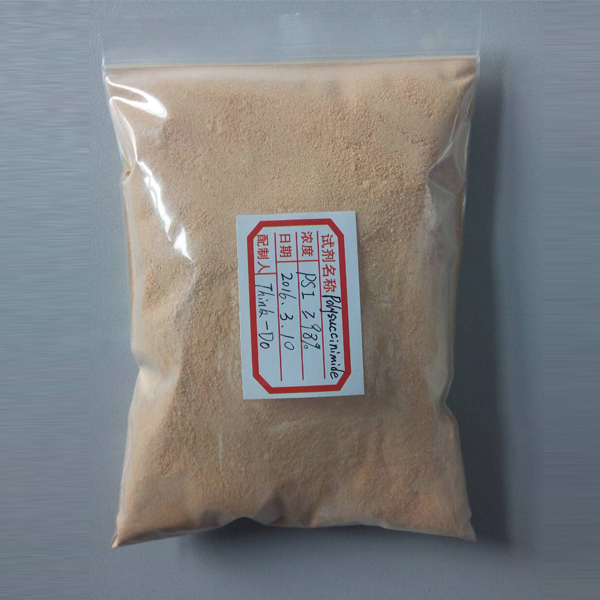

ce certification sodium chelator

1. Assessment of Characteristics Manufacturers need to assess the properties of the sodium chelator, including its chemical composition, stability, and any potential risks associated with its use. This information is crucial in determining the applicable directives.

2. Testing and Evaluation Accredited testing laboratories evaluate the sodium chelator against specific standards. This might include testing for efficacy in binding metal ions, toxicity levels, and environmental impact. The results of these tests contribute to the certification process.

3. Technical Documentation Manufacturers must prepare a technical file that includes all necessary documentation. This may include product specifications, test results, and risk assessments, which demonstrate compliance with relevant standards.

4. Declaration of Conformity After successful evaluation, manufacturers issue a Declaration of Conformity, which states that the product meets all the required standards. This declaration, along with the CE marking, must accompany the product when it is placed on the market.

5. Continuous Monitoring CE certification is not a one-time event. Manufacturers must continuously monitor their products and processes to ensure ongoing compliance with European regulations. Any changes in formulation or production methods may necessitate re-evaluation.

Challenges in CE Certification

While the benefits of CE certification for sodium chelators are significant, the process can also pose challenges. Manufacturers often face hurdles such as the complexity of regulatory requirements and the need for extensive testing. Additionally, the costs associated with achieving and maintaining CE certification can be substantial, particularly for smaller companies.

Conclusion

In summary, CE certification is essential for manufacturers of sodium chelators who wish to access the European market. It not only provides a competitive edge and promotes consumer confidence but also ensures compliance with stringent regulations. While the process can be challenging, the advantages of obtaining CE certification far outweigh the difficulties. As the demand for safe and effective sodium chelators continues to grow, manufacturers must prioritize compliance to maximize their business opportunities and uphold product integrity.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025