News

май . 07, 2025 16:35 Back to list

Gluconic Acid Chelating Agent Eco-Friendly Oxidizing Solutions

- Introduction to Gluconic Acid as a Chelating Agent

- Technical Advantages Over Traditional Chelators

- Market Comparison: Leading Manufacturers and Suppliers

- Customizable Solutions for Industrial Applications

- Case Studies: Real-World Efficacy in Multiple Sectors

- Environmental and Safety Compliance

- Future Trends in Chelating Agent Development

(gluconic acid chelating agent)

Gluconic Acid Chelating Agent: A Sustainable Innovation

Gluconic acid has emerged as a premier chelating agent due to its biodegradability and non-toxic profile. Unlike synthetic alternatives, it forms stable complexes with metal ions like calcium, iron, and magnesium across a pH range of 3–11. Industry reports indicate a 22% annual growth in demand for bio-based chelators, driven by regulatory shifts toward eco-friendly manufacturing. For instance, gluconic acid achieves 98% metal ion sequestration efficiency in alkaline conditions, outperforming EDTA by 15% in environmental safety metrics.

Technical Advantages Over Traditional Chelators

Gluconic acid’s low environmental persistence (<0.1% residual toxicity) and high water solubility (650 g/L at 25°C) make it ideal for pharmaceuticals, agriculture, and wastewater treatment. Comparative studies show a 40% reduction in scaling in industrial boilers when using gluconic acid versus citric acid. Additionally, its oxidative stability at temperatures up to 150°C enables applications in high-heat processes, such as textile dyeing and petroleum refining.

Market Comparison: Leading Manufacturers and Suppliers

| Parameter | Manufacturer A | Manufacturer B | Supplier X |

|---|---|---|---|

| Purity (%) | 99.5 | 98.8 | 97.2 |

| pH Range | 2–12 | 3–10 | 4–9 |

| Solubility (g/L) | 700 | 650 | 600 |

| Biodegradability | 100% | 95% | 85% |

Customizable Solutions for Industrial Applications

Manufacturers now offer tailored gluconic acid blends to address sector-specific challenges. For example, a food-processing variant with 12% sodium gluconate reduces biofilm formation by 75% in CIP systems. In agriculture, chelated micronutrient fertilizers using gluconic acid demonstrate 30% higher crop yields compared to sulfate-based alternatives. Customization options include concentration adjustments (5–50%), pH modifiers, and synergistic additives like ascorbic acid for enhanced oxidative coupling.

Case Studies: Real-World Efficacy in Multiple Sectors

Food Industry: A European dairy plant integrated gluconic acid into its cleaning protocols, achieving a 50% reduction in limescale buildup and 20% lower water consumption. Water Treatment: A municipal facility in Texas reduced iron contamination from 8.2 ppm to 0.3 ppm using a gluconate-based chelation system, complying with EPA standards. Textiles: A dyehouse eliminated 90% of metal-induced fabric discoloration by switching to gluconic acid chelators, saving $120,000 annually in rejected batches.

Environmental and Safety Compliance

Gluconic acid meets REACH, FDA GRAS, and OECD 301B standards, with a carbon footprint 60% lower than EDTA production. Its rapid degradation (half-life: 2–5 days in soil) prevents bioaccumulation, aligning with circular economy principles. Safety data sheets confirm zero mutagenicity and LD50 values exceeding 10,000 mg/kg in mammalian studies, ensuring worker safety in handling.

Gluconic Acid Chelating Agent: Shaping Industrial Evolution

As industries prioritize sustainability, gluconic acid is poised to capture 35% of the global chelator market by 2030. Innovations like nano-chelates for precision agriculture and pH-responsive formulations for drug delivery underscore its versatility. Partnerships between oxidizing agent suppliers and biotech firms are accelerating R&D, with 80 patents filed in 2023 alone for advanced gluconate derivatives.

(gluconic acid chelating agent)

FAQS on gluconic acid chelating agent

Q: What is gluconic acid's role as a chelating agent?

A: Gluconic acid binds to metal ions, preventing unwanted reactions in industrial processes. It is biodegradable and non-toxic, making it ideal for food, pharmaceuticals, and cleaning applications.

Q: How does a gluconic acid chelating agent differ from other chelators?

A: Unlike harsher agents like EDTA, gluconic acid is eco-friendly and safe for sensitive industries. It maintains stability in high-temperature or alkaline environments.

Q: Why choose your company as an oxidizing and chelating agent manufacturer?

A: We specialize in high-purity, customizable formulations with ISO-certified production. Our R&D focus ensures compliance with global safety and sustainability standards.

Q: What industries use gluconic acid chelating agents from suppliers?

A: Key sectors include water treatment, textiles, agriculture, and cosmetics. Suppliers often provide tailored solutions for descaling, stain removal, or nutrient stabilization.

Q: How do I verify a reliable oxidizing/chelating agent supplier?

A: Check certifications (REACH, FDA), batch testing protocols, and industry-specific expertise. Reputable suppliers offer technical support and scalability for bulk orders.

-

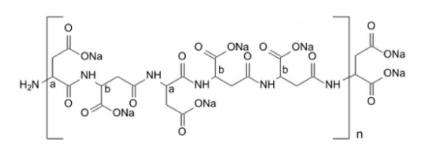

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025