News

dec . 04, 2024 23:08 Back to list

chelant corrosion boiler supplier

Chelant Corrosion in Boilers A Supplier’s Perspective

Boiler systems play a critical role in various industrial processes, providing steam and heat for production lines, power generation, and heating. However, these systems are susceptible to corrosion, leading to costly downtime and maintenance. One effective way to mitigate this problem is through the use of chelating agents. As a supplier of boiler chemicals, understanding the role of chelants in controlling corrosion is essential for ensuring the longevity and efficiency of boiler systems.

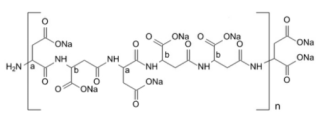

Understanding Chelants

Chelants are chemical compounds that can form multiple bonds with a single metal ion, effectively grabbing and stabilizing it in solution. This property makes them invaluable in various applications, particularly in mitigating corrosion. In boiler systems, the presence of dissolved metals can lead to scale formation, pitting, and overall degradation of the metal surfaces. By employing chelants, suppliers can help maintain water quality, ensuring that metal ions like iron and copper do not contribute to corrosion processes.

The Mechanism of Action

Chelants work primarily by sequestering metal ions that are responsible for corrosion. When these metal ions are captured, they are rendered inactive and unable to participate in electrochemical reactions that lead to corrosion. This not only protects the metal surfaces of the boiler but also maintains the integrity of the water quality. For example, ethylenediaminetetraacetic acid (EDTA) and nitrilotriacetic acid (NTA) are common chelants used in various boiler applications, effectively binding with harmful metals and preventing their precipitation as scale.

Benefits of Using Chelants in Boiler Systems

1. Corrosion Control The primary advantage of using chelants is corrosion protection. By controlling metal ion concentration in the boiler water, suppliers can prevent localized corrosion, which often leads to catastrophic failures.

chelant corrosion boiler supplier

2. Scale Prevention Scale buildup is a significant issue in boiler operation. Chelants not only control corrosion but also help prevent scale formation by keeping metal ions in solution, thereby reducing the amount of hard deposits formed on heat exchange surfaces.

3. Improved Efficiency Maintaining a corrosion-free and scale-free environment allows for more efficient heat transfer, which can improve the overall efficiency of the boiler system. This translates to reduced energy consumption and lower operating costs.

4. Operational Longevity Boilers that are well-protected against corrosion tend to last longer, reducing the need for frequent maintenance and replacement. This longevity is a significant cost-saver for businesses relying on these systems for their operations.

Considerations for Suppliers

As a supplier of boiler chemicals, understanding the specific needs of clients is essential. The choice of chelant depends on various factors, including the type of boiler, the quality of the feedwater, and the intended application. It’s crucial to offer tailored solutions that meet the unique requirements of each system.

Additionally, properly educating clients on the correct dosages and application methods for chelants can maximize their effectiveness. Regular monitoring of water chemistry is also vital to ensure that chelant levels remain optimal and that any potential issues can be addressed promptly.

Conclusion

The role of chelants in controlling corrosion within boiler systems cannot be overstated. As a supplier, providing effective chelating agents can significantly enhance the performance and durability of boiler systems, ultimately leading to cost savings and improved operational efficiency. By staying informed on the latest developments in chelation chemistry and understanding client needs, suppliers can deliver innovative solutions that address the challenges of corrosion while ensuring reliable boiler operation. The pursuit of excellence in boiler performance begins with comprehensive water treatment strategies that incorporate the effective use of chelants.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025