News

dec . 25, 2024 12:52 Back to list

OEM Biodegradation Study of AES Chelant and Its Environmental Impact

Biodegradation of AES Chelant An OEM Perspective

Chelating agents play a critical role in numerous industrial applications, particularly in cleaning products, fertilizers, and metal finishing. Among these, the amino ethyl ethanolamine (AES) chelant stands out due to its effectiveness in binding metal ions and enhancing product performance. However, environmental concerns surrounding the persistent nature of chelants have prompted researchers and manufacturers to seek more sustainable alternatives. One promising approach is the investigation into the biodegradation of AES chelants, particularly from the perspective of Original Equipment Manufacturers (OEMs).

Biodegradation refers to the breakdown of organic substances by natural processes, especially through the action of microorganisms. For OEMs, understanding the biodegradability of AES chelants is essential not only for regulatory compliance but also for meeting increasing consumer demands for environmentally friendly products. The potential for AES to undergo biodegradation can significantly influence product formulation decisions, marketing strategies, and overall brand reputation.

The primary environmental concern with synthetic chelating agents like AES is their tendency to persist in the environment, leading to potential bioaccumulation and toxicity in aquatic ecosystems. Consequently, the focus has shifted toward assessing the biodegradation rates of these compounds in various environments, including soil and water. Studies have shown that while AES chelants may exhibit some resistance to immediate breakdown, certain microbial communities can metabolize these compounds over time.

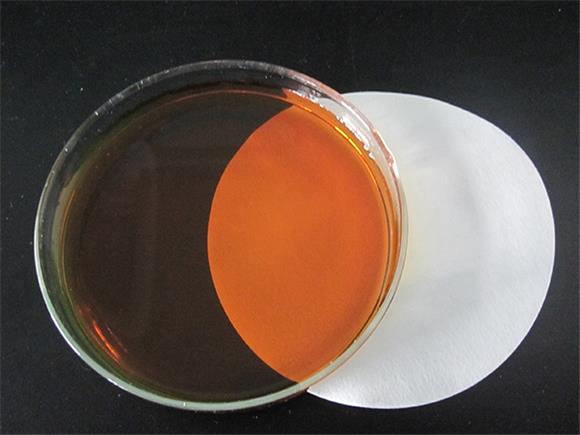

oem biodegradation of aes chelant

From an OEM's perspective, the biodegradation of AES chelants can offer several advantages. Firstly, products formulated with biodegradable agents are often viewed more favorably by consumers, increasing marketability. In a world increasingly driven by ecological awareness, the ability to promote a product as biodegradable can differentiate it from competitors. Moreover, regulatory bodies are imposing stricter guidelines concerning the environmental impact of industrial chemicals. Developing products that feature biodegradable AES chelants can ensure compliance with these regulations, potentially reducing liability and fostering goodwill among consumers.

In terms of product development, OEMs can work in collaboration with researchers to enhance the biodegradability of AES chelants. This can include modifying the molecular structure or incorporating additives that promote microbial activity. The goal is to create formulations that not only perform well in their intended applications but also decompose effectively in natural environments. Additionally, conducting lifecycle assessments (LCAs) can further inform strategies that prioritize sustainability throughout every stage of a product's life, from production to disposal.

Furthermore, OEMs can play a proactive role in educating their customers about the benefits of using environmentally friendly products. By providing comprehensive information about the biodegradation of AES chelants and the importance of sustainability, manufacturers can help consumers make informed choices. This transparency can build trust and loyalty, positioning the brand as a leader in environmental stewardship.

In conclusion, the biodegradation of AES chelants presents significant opportunities for OEMs committed to sustainability. By understanding the ecological implications of their products and actively pursuing biodegradable alternatives, manufacturers can improve their market position, comply with regulatory demands, and meet the growing consumer preference for environmentally sound options. As industries continue to evolve, prioritizing biodegradability in chelating agents like AES will be essential for ensuring a more sustainable and eco-friendly future. Ultimately, this commitment to environmental responsibility will drive innovation, enhance product performance, and foster a healthier planet for generations to come.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025