News

jan . 06, 2025 10:50 Back to list

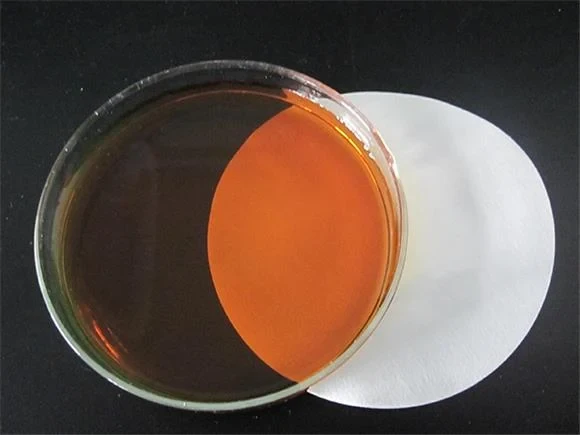

polyaspartic acid

Polyaspartic acid is gaining significant attention in various industries due to its unique properties that make it a superior choice for a range of applications. As an experienced professional in product optimization and enhancement, I can attest to the transformative impact this compound has had on product durability, environmental friendliness, and overall performance.

Derived from the natural polycondensation of L-aspartic acid, polyaspartic acid serves as a biodegradable alternative to conventional coatings and sealants. Its application spans across multiple sectors, from construction to automotive, showcasing its versatility and effectiveness. One of the standout features of polyaspartic acid is its rapid curing time. Compared to traditional epoxy and urethane coatings, polyaspartic layers set and dry at an accelerated rate, significantly reducing downtime. This advantage is critical in industrial settings where time efficiency translates to cost savings.

Furthermore, the exceptional resistance of polyaspartic coatings to ultraviolet light exposure ensures longevity and color stability, making it an ideal choice for outdoor applications. For automotive surfaces or external building facades, this property mitigates the common problem of yellowing and deterioration under harsh sunlight, thus maintaining aesthetic appeal for extended periods.

From an expertise standpoint, polyaspartic acid demonstrates remarkable adhesion to a variety of substrates. Whether applied to concrete, wood, or metal, it forms a robust bond that enhances the item’s structural integrity. Additionally, its chemical resistance sets it apart from other compounds; it withstands exposure to oils, fuels, and solvents, which prevents breakdown and extends the life of the coated surface.

polyaspartic acid

In terms of environmental impact, polyaspartic acid is an eco-conscious choice. Its derivation from natural components ensures that it breaks down more readily than traditional petrochemical-based coatings. This characteristic aligns well with the growing global emphasis on sustainability and ecological responsibility. Manufacturing processes that incorporate polyaspartic acid can thus address eco-regulatory requirements more effectively while contributing to the reduction of volatile organic compounds (VOCs) in the atmosphere.

For product developers and engineers, trustworthiness and reliability are paramount, and polyaspartic acid does not disappoint. Its proven track record across numerous high-demand applications instills confidence in its capabilities. Real-world case studies have documented the successes of polyaspartic coatings in extending the lifespan of industrial floors and maintaining the resilience of heavy-duty machinery parts, attesting to its robustness under stress and wear.

Lastly, its flexibility in application methods—whether spray, brush, or roller—further bolsters its appeal, allowing for customization based on project specifications and constraints. This adaptability ensures that polyaspartic acid can be utilized efficiently across different project scales and scopes, reaffirming its status as a go-to solution for modern industry needs.

In summary, polyaspartic acid stands as a testament to innovation in materials science, offering unparalleled benefits in efficiency, durability, environmental compatibility, and versatility. Its adoption across diverse industries is a clear indicator of its role as a pioneering product in advancing both economic and ecological objectives. As industries continue to evolve and prioritize sustainability alongside performance, polyaspartic acid will undoubtedly remain at the forefront of material advancements, driving forward an era of responsible and effective product solutions.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025