News

Pro . 09, 2024 17:32 Back to list

Polyaspartic Acid Infrared Applications and Manufacturing Insights for Industry Professionals

The Role of Polyaspartic Acid in Infrared Applications Innovations from the Factory

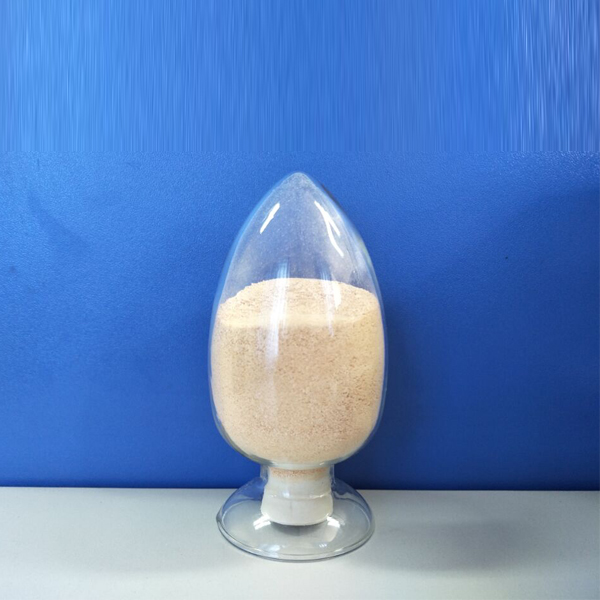

Polyaspartic acid (PASP) has emerged as a pivotal compound in various industrial applications, notably in the field of infrared technology. As a derivative of aspartic acid, PASP offers unique properties that have garnered attention from researchers and manufacturers alike. This article delves into the significance of polyaspartic acid in infrared applications, explores its synthesis, and highlights the innovations stemming from modern factories.

Understanding Polyaspartic Acid

Polyaspartic acid is a biodegradable polymer that is synthesized through the polymerization of aspartic acid. Its structure consists of repeating units that provide flexibility and functionality, making it suitable for a range of applications. One of the primary advantages of PASP is its excellent solubility in water, which facilitates its use in formulations where water-based solutions are preferred.

Infrared Applications

Infrared technology encompasses a broad range of applications, from sensors and imaging systems to heating elements and coatings. The unique properties of polyaspartic acid make it an attractive choice for enhancing the efficiency and effectiveness of these applications.

1. Infrared Coatings Polyaspartic acid-based coatings are increasingly being used in industry due to their superior adhesion, durability, and resistance to UV degradation. These coatings are applied to surfaces that require protection from environmental factors while maintaining their infrared reflectivity. This is particularly crucial in sectors such as automotive, aerospace, and construction, where material integrity is paramount.

2. Thermal Stability The thermal characteristics of PASP contribute to its use in infrared emissivity and reflectivity applications. Its ability to withstand high temperatures without significant degradation ensures that devices utilizing infrared technology can perform optimally under various temperature conditions.

3. Sensing and Detection Polyaspartic acid can be integrated into sensor technologies, where it may be used to develop sensitive infrared detectors. These detectors can be leveraged in diverse fields, including environmental monitoring, industrial automation, and security systems.

polyaspartic acid infrared factory

Innovations in Manufacturing

The production of polyaspartic acid has seen significant advancements in recent years, particularly in factories specializing in high-performance polymers. The adoption of cutting-edge technologies has led to improvements in efficiency, sustainability, and product quality.

1. Sustainable Production Modern factories are increasingly focusing on sustainable manufacturing practices. By utilizing renewable resources for the synthesis of polyaspartic acid, companies can reduce their environmental footprint. Additionally, the biodegradability of PASP aligns with the growing demand for eco-friendly materials in various industries.

2. Quality Control The implementation of advanced quality control systems in the manufacturing process ensures that the polyaspartic acid produced meets stringent industry standards. Automated monitoring and testing protocols facilitate consistent product quality, which is essential for applications in sensitive fields like electronics and healthcare.

3. Research and Development Factories that specialize in polyaspartic acid production are often at the forefront of research and development. They invest in exploring new formulations and enhancing the properties of PASP, leading to innovative applications in infrared technology. Collaborative efforts with academic institutions and industry partners further drive advancements in this area.

Conclusion

The significance of polyaspartic acid in infrared applications cannot be overstated. Its unique characteristics, such as excellent solubility, thermal stability, and biodegradability, position it as a valuable material in a range of industries. As factories continue to innovate and refine the production of PASP, we can expect to see even more applications emerge, enhancing the capabilities of infrared technology.

In a world that increasingly values sustainability and efficiency, polyaspartic acid stands out as a compound that not only meets the demands of modern manufacturing but also contributes to a greener future. With ongoing research and development, the potential of PASP in infrared applications is bound to expand, paving the way for groundbreaking technologies and solutions in the years to come.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025