News

nov . 19, 2024 21:32 Back to list

Innovative Chelating Agents for Efficient Copper Extraction in Industrial Processes

Chelating Agents for Copper Extraction Enhancing Efficiency in Copper Factories

Copper plays a vital role in various industries, from electrical wiring to plumbing, due to its excellent conductivity and corrosion resistance. As the demand for copper continues to rise, copper factories are increasingly exploring innovative methods to enhance extraction efficiency. One promising approach involves the use of chelating agents, which can significantly improve the process of copper recovery from ores and recycled materials.

Understanding Chelating Agents

Chelating agents are organic compounds that can bind to metal ions, forming stable, water-soluble complexes. This property makes them particularly useful in metal extraction processes. Chelating agents can selectively bind copper ions, facilitating their separation from other metals and impurities. This selectivity not only improves the purity of the extracted copper but also reduces the overall environmental impact of the extraction process.

The Role of Chelating Agents in Copper Extraction

In traditional copper extraction methods, such as hydrometallurgy and pyrometallurgy, high temperatures and aggressive chemicals are often required. These methods can be energy-intensive and environmentally damaging. In contrast, the incorporation of chelating agents can make the process more sustainable. By using milder conditions and less toxic reagents, copper factories can reduce energy consumption and minimize waste generation.

Chelating agents work effectively in leaching processes, where they dissolve metal salts from ores or scrap materials. When a chelating agent is introduced into the solution containing copper ions, it forms a complex with the copper, subsequently increasing its solubility. This enhances the efficiency of the leaching process, allowing for higher copper yields. Common chelating agents used in copper extraction include ethylenediaminetetraacetic acid (EDTA), citric acid, and various amino acids.

Applications in Copper Factories

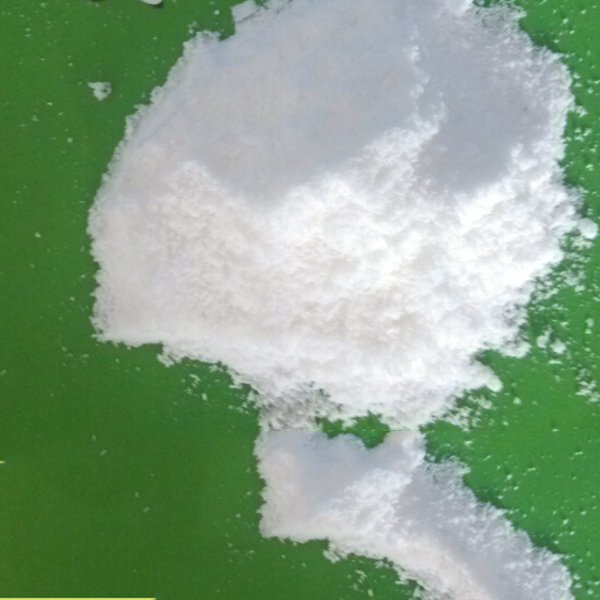

chelating agent for copper factory

Copper factories are actively adopting chelating agents to optimize their operations. For instance, in the bioleaching process, where microorganisms are used to extract metals, chelating agents can facilitate the bioavailability of copper ions, encouraging microbial activity and improving metal recovery rates. This biotechnological approach is not only efficient but also environmentally friendly, as it reduces the need for harsh chemicals.

Moreover, the application of chelating agents extends beyond primary copper extraction. In recycling processes, chelating agents can help recover copper from electronic waste (e-waste). E-waste contains significant amounts of precious metals, including copper, which are often locked in complex matrices. By using chelating agents, recyclers can selectively extract copper from these matrices, enhancing recovery rates and promoting resource efficiency.

Environmental Considerations

The environmental implications of chelating agents in copper extraction cannot be overlooked. While these agents can reduce the need for harmful chemicals and high-energy processes, their use must be carefully managed. Some chelating agents, such as EDTA, can persist in the environment and may have negative ecological effects if not properly treated before disposal. Therefore, it is crucial for copper factories to implement strategies to mitigate these risks, such as using biodegradable chelating agents or ensuring proper waste management practices.

Future Prospects

The future of copper extraction in factories appears promising with the continued development of advanced chelating agents. Research is focused on creating new, more efficient, and environmentally friendly chelating agents that can optimize the recovery of copper and other valuable metals. Innovations in this area could lead to reduced costs, improved efficiency, and lower environmental impact, aligning with the growing emphasis on sustainable practices in industry.

In conclusion, the integration of chelating agents into copper extraction processes presents a transformative opportunity for copper factories. By enhancing extraction efficiency and reducing environmental impact, chelating agents play a crucial role in meeting the increasing demands for copper while promoting sustainability. As technology evolves and research advances, the potential for chelating agents to revolutionize copper recovery will only grow, making them indispensable in the quest for efficient and responsible metal extraction practices.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025