News

Jan . 09, 2025 10:40 Back to list

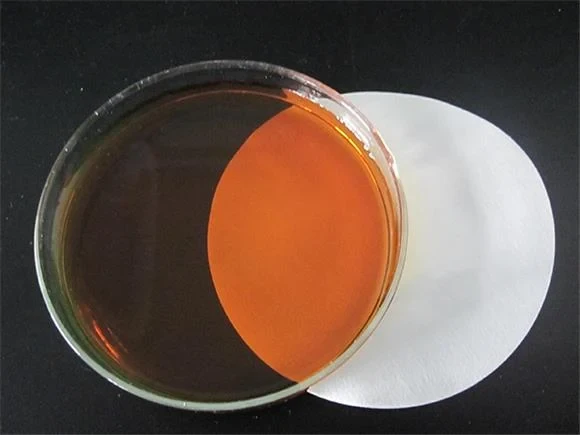

High-quality and Readily-effective micronutrients—EDDHA

Delving into the world of advanced coatings, polyaspartic acid sodium salt emerges as a transformative player, especially in the realm of durable, high-performance surfaces. This cutting-edge material not only enhances the longevity of applications but also reflects modern advancements that prioritize both quality and environmental sustainability.

Moreover, environmental considerations have become increasingly crucial in product development. Thankfully, polyaspartic acid sodium salt aligns perfectly with sustainability goals. Its formulation minimizes volatile organic compound (VOC) emissions, reflecting a conscientious step towards reducing environmental impact. Companies striving to meet green building certification standards will find this material to be a strategic ally. In essence, authority in the field of advanced coatings doesn't come from merely understanding the chemical composition, but from recognizing the transformative impact these innovations have across sectors. Polyaspartic acid sodium salt moves beyond the limitations of conventional materials, offering a solution that is as reliable as it is revolutionary. Project planners and decision-makers must look beyond initial investments to see the long-term value and durability that this material introduces. Trust in a product often relies on its real-world validation. Many industries have already adopted this compound with great success, attesting to its dependability and high-performance nature. Whether in flooring systems of industrial warehouses or the protective layers of modern automotive finishes, the evidence speaks volumes—polyaspartic acid sodium salt not only meets but surpasses expectations. Through informed choices and adoption of innovative materials like polyaspartic acid sodium salt, industries can spearhead a new era of high-performance, sustainable, and cost-effective solutions in surface coatings. With its proven effectiveness and environmental benefits, this compound is poised to remain at the forefront of materials engineering for years to come.

Moreover, environmental considerations have become increasingly crucial in product development. Thankfully, polyaspartic acid sodium salt aligns perfectly with sustainability goals. Its formulation minimizes volatile organic compound (VOC) emissions, reflecting a conscientious step towards reducing environmental impact. Companies striving to meet green building certification standards will find this material to be a strategic ally. In essence, authority in the field of advanced coatings doesn't come from merely understanding the chemical composition, but from recognizing the transformative impact these innovations have across sectors. Polyaspartic acid sodium salt moves beyond the limitations of conventional materials, offering a solution that is as reliable as it is revolutionary. Project planners and decision-makers must look beyond initial investments to see the long-term value and durability that this material introduces. Trust in a product often relies on its real-world validation. Many industries have already adopted this compound with great success, attesting to its dependability and high-performance nature. Whether in flooring systems of industrial warehouses or the protective layers of modern automotive finishes, the evidence speaks volumes—polyaspartic acid sodium salt not only meets but surpasses expectations. Through informed choices and adoption of innovative materials like polyaspartic acid sodium salt, industries can spearhead a new era of high-performance, sustainable, and cost-effective solutions in surface coatings. With its proven effectiveness and environmental benefits, this compound is poised to remain at the forefront of materials engineering for years to come.

Latest news

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025