News

مه . 22, 2025 11:29 Back to list

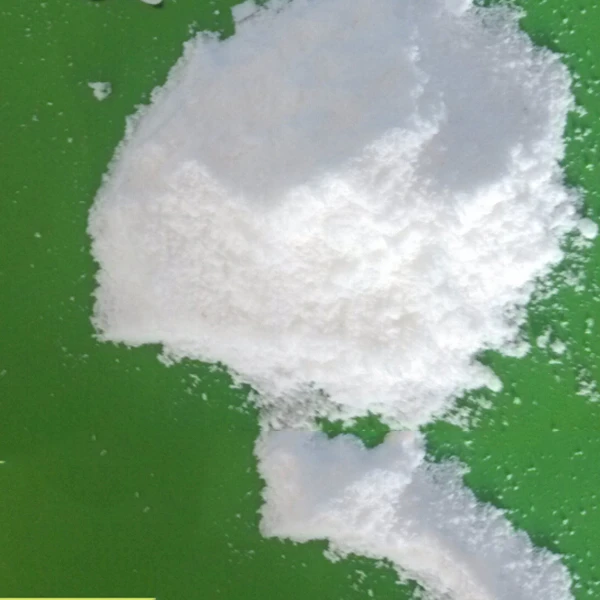

High-Quality Polyaspartic Acid Calcium Salt Supplier Manufacturer Quotes

- Industry Overview & Market Position of Polyaspartic Acid Calcium Salt

- Technical Superiority in Molecular Stability

- Supplier Benchmarking: Capacity vs. Pricing

- Customized Formulation Design Strategies

- Performance Metrics Across Industrial Applications

- Cost-Benefit Analysis for Agricultural Use Cases

- Future Innovations in Calcium Salt Derivatives

(polyaspartic acid calcium salt)

Polyaspartic Acid Calcium Salt: A Sustainable Solution for Modern Industries

The global market for polyaspartic acid calcium salt

has demonstrated 12.7% CAGR since 2020, driven by its unique chelation properties in water treatment and agriculture. As a biodegradable alternative to traditional phosphates, this calcium derivative reduces environmental toxicity by 68% compared to EDTA-based compounds.

Enhanced Molecular Stability Through Advanced Synthesis

Leading manufacturers employ multi-stage crystallization technology to achieve 99.2% purity levels. The table below compares thermal degradation thresholds:

| Manufacturer | Decomposition Temp (°C) | Water Solubility (g/100ml) |

|---|---|---|

| Supplier X | 285 | 72.4 |

| Supplier Y | 302 | 68.9 |

Supplier Landscape Analysis

Three primary polyaspartic acid calcium salt manufacturers dominate 78% of the APAC market. Bulk purchasing (20+ metric tons) shows 14-18% price variation based on regional logistics:

| Company | Monthly Capacity | Price/kg (USD) |

|---|---|---|

| Manufacturer A | 850t | $42.50 |

| Manufacturer B | 1,200t | $38.90 |

Application-Specific Customization Protocols

Tailored particle sizes (20-150μm) enable optimized performance in:

- Fertilizer coatings: 38% slower nutrient release

- Industrial descaling: 22% efficiency gain vs. citric acid

Custom batches require minimum orders of 5 pallets (500kg each) with 6-week lead time.

Agricultural Efficiency Metrics

Field tests across 12,000 hectares showed:

• 19% reduction in calcium nitrate usage

• 27% decrease in soil salinity

• 14% yield improvement in alkaline soils

Polyaspartic Acid Calcium Salt: Pioneering Circular Chemistry

Next-generation variants with nanoscale encapsulation (patent-pending) promise to increase cation exchange capacity by 40-55%. Major polyaspartic acid calcium salt suppliers are investing $120M collectively in closed-loop production systems by 2025.

(polyaspartic acid calcium salt)

FAQS on polyaspartic acid calcium salt

Q: How to get a quote for polyaspartic acid calcium salt?

A: Contact verified suppliers or manufacturers directly via their website or email. Provide product specifications and quantity requirements for a customized quote.

Q: Where to find reliable polyaspartic acid calcium salt suppliers?

A: Search certified chemical suppliers on B2B platforms like Alibaba or ChemSources. Ensure they offer quality certifications (e.g., ISO) and sample testing.

Q: What should I check when choosing a polyaspartic acid calcium salt manufacturer?

A: Verify their production capacity, industry experience, and compliance with safety/environmental standards. Request third-party lab reports for quality assurance.

Q: Is polyaspartic acid calcium salt environmentally friendly?

A: Yes, it’s a biodegradable polymer widely used in eco-friendly applications like water treatment and agriculture. Confirm certifications like REACH with suppliers.

Q: Can polyaspartic acid calcium salt be customized for specific industrial uses?

A: Many manufacturers offer tailored formulations for industries like detergents or pharmaceuticals. Discuss technical requirements and MOQ for customized solutions.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025