News

دسامبر . 29, 2024 05:59 Back to list

polymer of aspartic acid factory

The Aspartic Acid Polymer Factory Revolutionizing Biopolymer Production

In recent years, the demand for sustainable and environmentally friendly materials has led to significant advancements in the field of biopolymers. One such notable biopolymer is aspartic acid polymer, derived from the amino acid aspartic acid. The establishment of dedicated factories for the production of aspartic acid polymers plays a crucial role in meeting this demand while contributing to a greener future.

Aspartic acid, a non-essential amino acid, is pivotal in various biological processes and has versatile applications in the industrial sector. It serves as a building block for proteins and plays a vital role in the synthesis of neurotransmitters. However, in the context of polymer production, aspartic acid is predominantly utilized to create polyaspartic acid, a biodegradable polymer that finds applications in diverse fields, ranging from agriculture to pharmaceuticals.

The Production Process

The production of aspartic acid polymers involves several steps, beginning with the extraction of aspartic acid from natural sources or through chemical synthesis. The traditional methods include fermentation processes using microorganisms, which convert glucose or other carbohydrate sources into aspartic acid. This biotechnological approach not only provides a renewable source for the amino acid but also minimizes the environmental impact compared to conventional chemical synthesis methods.

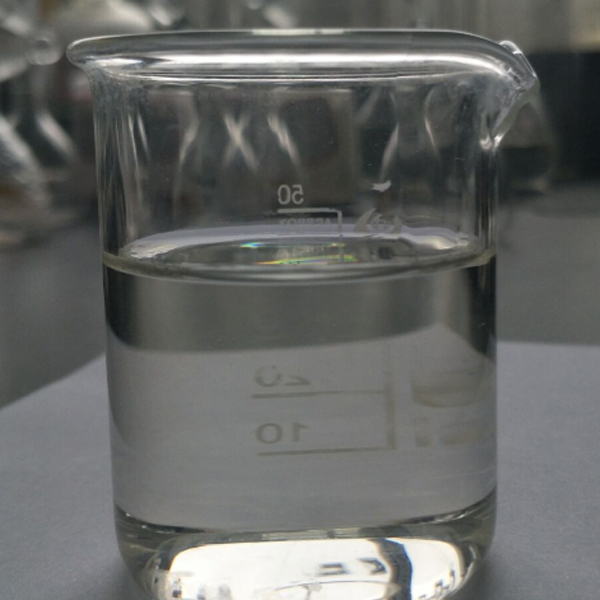

Once aspartic acid is obtained, the polymerization process can begin. In the factory, aspartic acid undergoes a chemical reaction to form polyaspartic acid. This process can involve various catalysts or conditions, such as heat and pressure, to facilitate the reaction. The versatility in production methods allows manufacturers to tailor the properties of the final polymer, adjusting factors like molecular weight and solubility to suit specific applications.

Applications of Aspartic Acid Polymers

Polyaspartic acid is renowned for its biodegradable nature, making it an attractive alternative to petroleum-based polymers. One of the prominent applications of aspartic acid polymers is in agriculture, where they are used as superabsorbent materials. These polymers can retain significant volumes of water, improving soil moisture retention and enhancing plant growth in arid regions.

polymer of aspartic acid factory

Moreover, aspartic acid polymers have shown potential in the field of pharmaceuticals. They can be utilized for drug delivery systems due to their biocompatibility and controlled release properties. This application is crucial in developing targeted therapies that minimize side effects while maximizing therapeutic efficacy.

In addition to agricultural and pharmaceutical applications, aspartic acid polymers are finding their way into the construction and coatings industry. Their water-resistant properties make them suitable for formulating eco-friendly paints and coatings that do not release harmful volatile organic compounds (VOCs) into the atmosphere. This aligns with the global push towards sustainable building materials and eco-conscious manufacturing processes.

Environmental Impact and Sustainability

The establishment of aspartic acid polymer factories aligns with the growing emphasis on sustainability in manufacturing. By leveraging renewable resources, these factories not only reduce reliance on fossil fuels but also contribute to waste reduction and lower carbon emissions. Furthermore, the biodegradable nature of polyaspartic acid ensures that products made from this polymer do not contribute to long-term environmental pollution, a major concern with traditional plastics.

These factories also adhere to stringent environmental regulations, implementing advanced waste treatment processes to minimize their ecological footprint. Investments in research and development are ongoing, focusing on enhancing the efficiency of production methods and exploring innovative applications for aspartic acid polymers.

Conclusion

The aspartic acid polymer factory represents a significant milestone in the evolution of biopolymer production. As industries across the globe seek sustainable alternatives to conventional materials, the role of aspartic acid polymers will only continue to grow. With their diverse applications and environmentally friendly properties, these biopolymers stand at the forefront of the transition towards a more sustainable economy. The future of manufacturing lies in such innovations, where the intersection of technology and ecology paves the way for a healthier planet.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025