News

joulu . 05, 2024 11:20 Back to list

Insights on the Synthesis of Polyglutamic Acid and Its Applications in Biotechnology

Polyglutamic Acid Synthesis Insights and Innovation

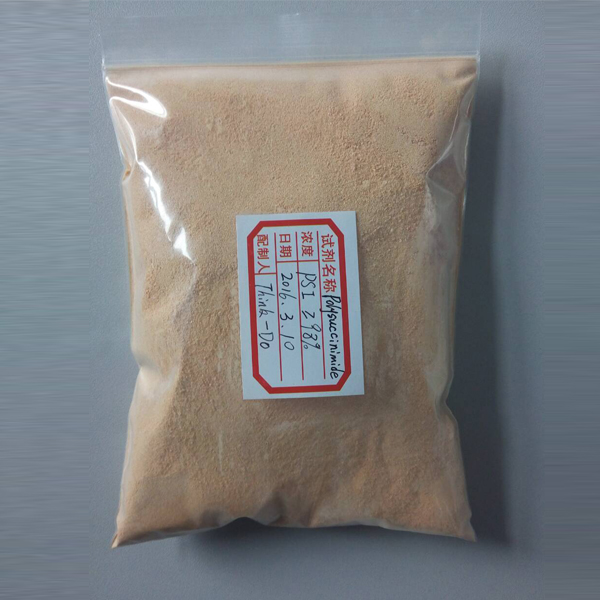

Polyglutamic acid (PGA) is a naturally occurring biopolymer composed of glutamic acid residues linked together through peptide bonds. It has garnered significant attention due to its biocompatibility, biodegradability, and unique properties, making it an attractive candidate for various applications in the fields of medicine, agriculture, and food technology. The synthesis of polyglutamic acid, particularly in controlled and efficient ways, is a topic of vibrant research and innovation. This article explores the synthesis of polyglutamic acid, highlighting its methods, challenges, and potential applications.

Synthesis Methods

The synthesis of polyglutamic acid can be achieved through several approaches, including microbial fermentation and chemical synthesis. Among these, microbial fermentation is the most widely used method, as it benefits from being environmentally friendly and sustainable. Notably, certain strains of bacteria, such as *Bacillus subtilis*, are known for their ability to produce PGA naturally. Through fermentation, these bacteria utilize glutamate as a substrate, metabolizing it to produce polyglutamic acid.

One notable quote in the field is, “Microbial synthesis presents a profound opportunity to produce polyglutamic acid sustainably.” This statement encapsulates the significance of using natural processes to harness the advantages of PGA without relying heavily on synthetic chemistry. Researchers have been optimizing fermentation conditions—such as pH, temperature, and nutrient availability—to maximize yield, showcasing how advancements in biotechnology can drive the efficient production of biopolymers.

In addition to microbial synthesis, chemical methods have also been developed. For instance, polycondensation techniques that involve glutamic acid derivatives can yield PGA. However, these chemical processes often come with challenges such as low yield and the need for complex purification steps. As one researcher aptly noted, “While chemical synthesis offers a rapid route to polyglutamic acid, it’s the microbial path that truly embodies sustainability.” This reflects the ongoing debate in the scientific community about the best approaches to PGA synthesis.

Challenges in Synthesis

Despite the promising advances, the synthesis of polyglutamic acid faces several challenges. One significant hurdle is the scaling-up of microbial fermentation processes. Transitioning from laboratory-scale experiments to industrial production while maintaining efficiency and product quality is a complex task. Industrial fermenters must be carefully designed to optimize conditions that support bacterial growth and PGA production, all while minimizing costs.

polyglutamic acid synthesis quotes

Another challenge is the control of molecular weight and polymer structure. Polyglutamic acid can have varying properties depending on its molecular weight, which directly influences its applications. Achieving a consistent product is crucial, particularly for applications in drug delivery systems where controlled release is essential. An expert in the field remarked, “Understanding the relationship between synthesis parameters and polymer characteristics is key to unlocking the full potential of polyglutamic acid.”

Applications of Polyglutamic Acid

The potential applications of polyglutamic acid are vast and varied. In the medical field, its biocompatibility makes it suitable for use in drug delivery systems, tissue engineering, and wound healing. PGA can serve as a scaffold for cell growth and as a vehicle for the controlled release of therapeutic agents.

In agriculture, polyglutamic acid can enhance soil moisture retention and improve nutrient absorption, making it a valuable additive for fertilizers. Its biodegradable nature ensures that it contributes to more sustainable agricultural practices.

In the food industry, PGA can be utilized as a thickening agent, emulsifier, and stabilizer, enhancing the texture and quality of various food products. Its ability to retain moisture adds significant value, particularly in processed foods.

Conclusion

The synthesis of polyglutamic acid holds immense promise across multiple industries, driven by innovative research and sustainable practices. While challenges in production remain, the potential benefits of this biopolymer continue to inspire scientists and entrepreneurs alike. As we move forward, the integration of advanced biotechnological methods will likely pave the way for more efficient and scalable synthesis of polyglutamic acid, unlocking new opportunities for its application in our daily lives. The journey of polyglutamic acid synthesis exemplifies the intersection of science and sustainability, emphasizing the need for continued exploration and innovation in this exciting field.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025