News

syys . 28, 2024 18:32 Back to list

Additives for delaying setting time in calcium sulfate binders for construction applications

The Role of Retarders in Calcium Sulfate Binder Applications

Calcium sulfate binders, commonly utilized in construction and various industrial applications, have gained significant attention due to their favorable properties, such as quick setting times and ease of handling. However, there are circumstances where the rapid setting of these binders can pose challenges, particularly in large-scale applications. This is where retarders come into play, extending the working time and improving the overall performance of calcium sulfate binders.

Understanding Calcium Sulfate Binders

Calcium sulfate is a widely used binder in the form of gypsum, commonly found in construction materials such as plaster and drywall. When mixed with water, it forms a slurry that sets quickly into a solid form. The speed of setting can be advantageous in many scenarios, but in situations requiring detailed work, such as intricate moldings or repairs, the quick setting time can hinder the application process.

Retarders are chemical additives specifically designed to slow down the setting time of these binders. By incorporating a retarder into the mixture, builders and manufacturers can effectively manage the working time, allowing for easier manipulation and application before the material begins to harden.

Mechanism of Action

Retarders work on a chemical level, interfering with the hydration process of calcium sulfate. When water is added to calcium sulfate, the hydration reactions initiate the setting process. Retarders alter this reaction, creating a delay in the formation of gypsum crystals, which consequently extends the workable period of the mixture. This feature is particularly beneficial in hot weather conditions, where the rapid drying can lead to problems such as cracking and poor adhesion.

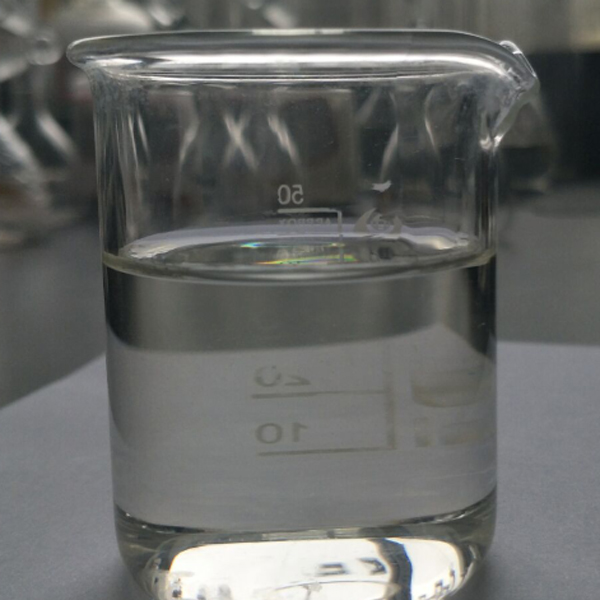

retarder for calcium sulfate binder

Types of Retarders

Several types of retarders are employed in conjunction with calcium sulfate binders. Common retarders include 1. Sugar and its Derivatives Natural sugars, such as sucrose, are known to effectively slow down the hydration process. Use of these organic compounds can be particularly appealing from an environmental perspective. 2. Starch-based Compounds Starches can also act as effective retarders, providing additional workability and enhancing the overall performance of the binder. 3. Synthetic Retarders Various synthetic chemicals and polymers are designed specifically for use as retarders in calcium sulfate applications. These can be tailored to achieve specific effects based on the needs of the project.

Applications of Retarded Calcium Sulfate Binders

The use of retarders in calcium sulfate binders opens up a range of applications in various fields

- Construction In large-scale construction projects where extensive detailing is required, retarders allow workers to have sufficient time to manipulate the material without the pressure of an imminent setting. - Artistic Casting In sculpting and artistic applications, retarders enable artists to work intricately with gypsum forms, ensuring precision and detail in their creations. - Repair Work In restoration and repair projects, where precision is critical, using a retarded binder ensures that the material can be applied evenly and without rush.

Conclusion

The incorporation of retarders in calcium sulfate binder applications has transformed how these materials are used in various industries. By extending the working time and improving performance, retarders inevitably enhance the versatility of calcium sulfate, making it suitable for an even broader range of applications. As the construction and manufacturing industries continue to demand efficient yet robust materials, the role of modifiers like retarders will likely expand, leading to innovations and advancements in binder technologies. In summary, the careful selection and application of retarders are essential for maximizing the effectiveness of calcium sulfate binders, ensuring superior results in both construction and artistic endeavors.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025