News

Oct . 17, 2024 16:27 Back to list

Flow-Enhanced Chelant Corrosion Mechanisms in Industrial Applications and Their Impact

Flow-Assisted Chelant Corrosion An Overview

Corrosion is a pervasive issue in many industries, particularly those that handle fluids, such as oil and gas, chemical manufacturing, and water treatment. Among the various types of corrosion, flow-assisted chelant corrosion (FAC) presents a significant challenge due to its complex interplay of fluid dynamics and chemical interactions. Understanding the mechanisms behind FAC, its implications, and mitigation strategies is crucial for maintaining the integrity of industrial systems.

What is Flow-Assisted Chelant Corrosion?

Flow-assisted chelant corrosion occurs when a metal surface is exposed to a flowing electrolyte that contains chelating agents. Chelating agents are compounds that can form multiple bonds with a single metal ion, effectively wrapping around the metal and enhancing its solubility in a solution. In conditions where these agents are present and flow rates are significant, they can lead to accelerated corrosion of metals, particularly in systems that utilize carbon steel or stainless steel components.

The mechanism of FAC involves several factors the availability of chelating agents in the solution, the velocity of fluid flow, and the properties of the metal substrate. When a chelating agent interacts with the metal surface in the presence of turbulent flow, it can promote localized corrosion processes that diminish the protective oxide layers typically formed on metals. This localized attack can lead to pitting, thinning of the material, and ultimately, structural failure.

Factors Influencing FAC

Several factors influence the rate and extent of flow-assisted chelant corrosion

1. Flow Velocity Increased flow velocity can exacerbate FAC by enhancing the transport of chelating agents to the metal surface. High-velocity conditions may cause erosive effects and lead to the breakdown of protective layers.

2. Concentration of Chelants The concentration of chelating agents in the solution plays a critical role. Higher concentrations can promote more aggressive corrosion behavior as more chelant molecules interact with the metal surface.

3. Temperature Elevated temperatures may enhance the chemical activity of both the chelating agents and the metal surface, leading to increased corrosion rates.

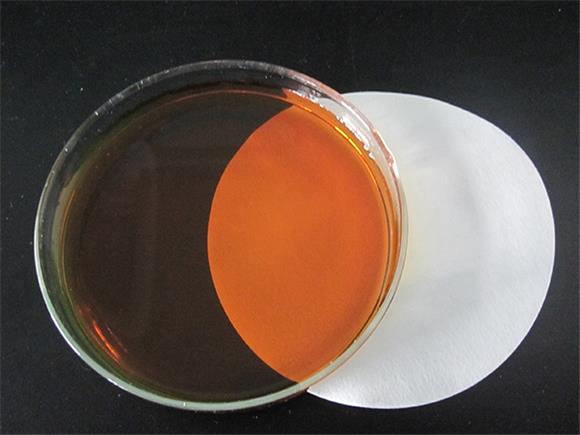

flow assisted chelant corrosion

4. pH Levels The pH of the solution can influence the effectiveness of chelating agents and the solubility of metal ions. Acidic conditions often favor enhanced corrosion processes.

5. Metal Composition Different metals exhibit varying resistances to chelant-induced corrosion, with some alloys being more susceptible than others to the effects of chelation.

Mitigation Strategies

To combat flow-assisted chelant corrosion, industries can implement several mitigation strategies

1. Chemical Inhibitors Introducing chemical inhibitors that can either passivate the metal surface or interfere with the chelation process can significantly reduce corrosion rates. These inhibitors may decrease the availability of free chelant agents or enhance the protective oxide layer.

2. Material Selection Utilizing corrosion-resistant alloys or coatings can significantly reduce the susceptibility to FAC. Materials with robust protective properties can withstand aggressive environments better than standard carbon steels.

3. Flow Management Adjusting flow rates and turbulence can help minimize the impact of FAC. Implementing flow restrictors or optimizing system designs may reduce high-velocity zones where corrosion is more likely to occur.

4. Regular Monitoring Implementing a monitoring program to assess corrosion rates, material conditions, and fluid properties is essential. Non-destructive testing methods such as ultrasonic thickness measurements can be valuable in detecting early signs of corrosion.

Conclusion

Flow-assisted chelant corrosion is a complex and challenging phenomenon that requires a comprehensive understanding of the underlying mechanisms and contributing factors. By implementing effective mitigation strategies, industries can significantly reduce the risks associated with FAC, thereby enhancing the reliability and longevity of critical infrastructure. As operations continue to advance and face more rigorous environments, awareness and proactive management of flow-assisted chelant corrosion will remain essential for ensuring safety and operational efficiency.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025