News

דצמ . 29, 2024 14:29 Back to list

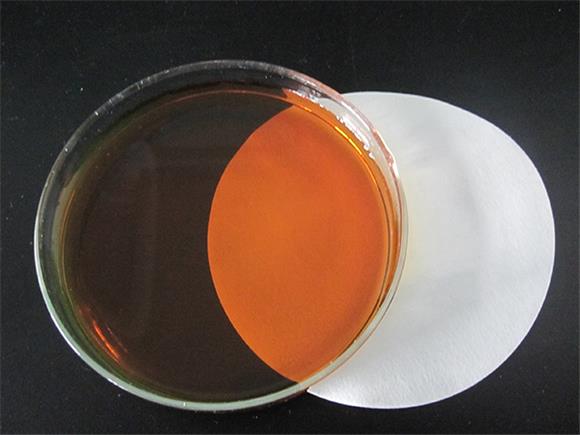

ordinary polyglutamic acid manufacturer

Understanding Ordinary Polyglutamic Acid Applications and Manufacturing

Polyglutamic acid (PGA) is a naturally occurring biopolymer that has gained attention in various industries, particularly in cosmetics, food, and pharmaceuticals. With the rising demand for sustainable and effective ingredients, ordinary polyglutamic acid manufacturers are increasingly focused on producing this versatile compound. This article delves into the significance of ordinary polyglutamic acid, its manufacturing processes, and its diverse applications.

What is Polyglutamic Acid?

Polyglutamic acid is a polymer made up of glutamic acid units linked by peptide bonds. It can be derived from natural sources, such as fermented soybeans, or synthesized through various chemical means. The structure of PGA allows it to retain water effectively, making it an ideal ingredient in moisture-retaining products. Its unique amino acid composition contributes to its biocompatibility and reduces irritation, making it suitable for sensitive skin applications.

Importance of Manufacturing Processes

The manufacturing process of ordinary polyglutamic acid is crucial in determining its quality and effectiveness. There are two primary methods for producing PGA microbial fermentation and chemical synthesis.

1. Microbial Fermentation This eco-friendly method involves using specific strains of bacteria, such as *Bacillus subtilis*, to ferment natural substrates. The fermentation process not only ensures high purity and yield but also aligns with sustainable practices. Manufacturers who adopt this method benefit from reduced environmental impact while catering to the growing consumer preference for natural ingredients.

2. Chemical Synthesis While less common, chemical synthesis can also be used for producing PGA. This method involves the direct polymerization of glutamic acid, allowing for precise control of the polymer's molecular weight. Although this approach can produce high-quality polyglutamic acid, it may involve the use of hazardous chemicals, which raises concerns regarding safety and environmental impact.

ordinary polyglutamic acid manufacturer

Applications of Ordinary Polyglutamic Acid

Ordinary polyglutamic acid has a wide range of applications across several industries

1. Cosmetics and Skincare One of the primary uses of PGA is in skincare formulations. Its ability to retain moisture is significantly higher than that of hyaluronic acid, making it a valuable ingredient for hydrating products. Manufacturers of creams, serums, and masks incorporate PGA to enhance skin hydration, elasticity, and overall appearance. Due to its gentle nature, it is also suitable for sensitive skin, reducing the likelihood of irritation and reactions.

2. Food Industry In the food sector, polyglutamic acid is used as a thickening and stabilizing agent. It can enhance the texture of various food products, making them more appealing to consumers. Moreover, its ability to improve moisture retention in processed foods contributes to prolonged freshness and shelf life. Consequently, food manufacturers are increasingly utilizing PGA as a natural alternative to synthetic additives.

3. Pharmaceuticals The pharmaceutical industry recognizes the potential of polyglutamic acid in drug delivery systems. Its biocompatibility allows for the encapsulation of drugs, resulting in improved stability and targeted delivery within the body. Additionally, PGA can be utilized in the development of hydrogels for wound healing applications, facilitating faster recovery and improved patient outcomes.

4. Agriculture In agriculture, polyglutamic acid serves as a natural soil conditioner and water-retaining agent. It aids in enhancing soil moisture retention, promoting better plant growth. With the rising concerns about water scarcity, the use of PGA in agriculture represents an effective method to optimize water use in farming practices.

Conclusion

The demand for ordinary polyglutamic acid continues to rise, driven by its versatility and effectiveness in various applications. As consumers become more aware of ingredient transparency and sustainability, manufacturers are increasingly focused on eco-friendly production methods. By leveraging microbial fermentation techniques, ordinary polyglutamic acid manufacturers can meet the needs of diverse industries while prioritizing environmental responsibility. As scientific research advances, the full potential of PGA is expected to unfold, paving the way for new applications in health, beauty, and beyond.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025