News

अक्टूबर . 12, 2024 21:18 Back to list

Production of Ordinary Polyglutamic Acid in a Modern Facility

The Innovative World of Ordinary Polyglutamic Acid Factories

In the field of biochemistry and biotechnology, polyglutamic acid (PGA) has emerged as a fascinating compound with a myriad of applications. Ordinary polyglutamic acid factories are at the forefront of producing this multifunctional biopolymer, which is derived from the fermentation of glutamic acid. From cosmetics to agriculture, the versatility of PGA has placed it in high demand, making the factories that produce it key players in various industries.

What is Polyglutamic Acid?

Polyglutamic acid is a naturally occurring polymer of the amino acid glutamic acid. It is a potent humectant, meaning it attracts and retains moisture, making it an essential ingredient in skincare. Beyond its hydrating properties, PGA also possesses film-forming abilities, enhancing product texture and stability. Its unique characteristics make it a critical component in products aimed at improving skin hydration and elasticity, thus gaining significant popularity in the cosmetics industry.

Moreover, the benefits of PGA are not limited to cosmetic applications. It is increasingly being used in agriculture due to its ability to improve soil quality and stimulate plant growth. Its water retention capabilities help in maintaining soil moisture, leading to better crop yields. This versatility sparks interest among manufacturers aiming to capitalize on the numerous advantages that PGA offers.

The Production Process in Polyglutamic Acid Factories

Ordinary polyglutamic acid factories typically employ a fermentation process using specific bacterial strains, such as *Bacillus subtilis*. This process is both sustainable and efficient, allowing for large-scale production while minimizing environmental impact. The fermentation process involves several stages, including the inoculation of bacterial cultures, fermentation, and purification of the final product.

The initial step involves preparing a nutrient-rich medium where bacteria can proliferate. The selected bacterial strains are inoculated into this medium, where they metabolize the available nutrients and produce polyglutamic acid as a by-product. This leads to a batch process where the production time may vary from several hours to days, depending on the desired yield.

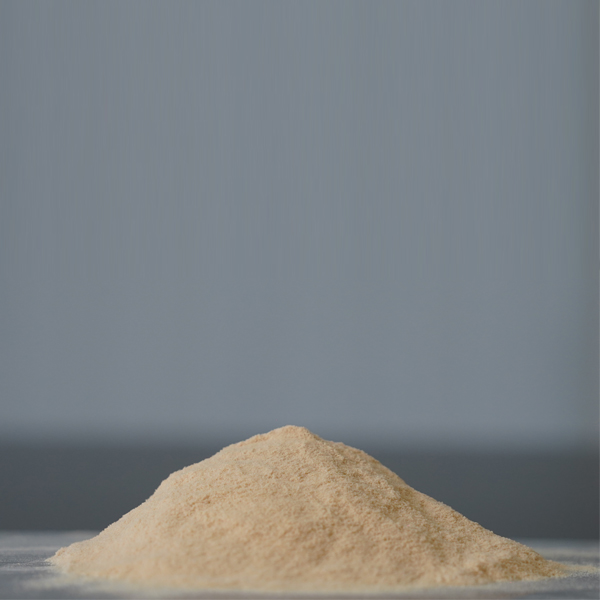

ordinary polyglutamic acid factory

Once the fermentation process is complete, the next phase involves harvesting the PGA from the culture broth. Various purification techniques, such as precipitation and filtration, are employed to isolate the polyglutamic acid. The final step includes drying and milling the product to achieve a fine powder that is easy to incorporate into various formulations.

Applications and Market Demand

The applications of ordinary polyglutamic acid are extensive. In the cosmetic industry, it is celebrated for its ability to enhance moisture retention, which is crucial for hydration-focused products such as serums, creams, and masks. PGA is also incorporated into hair care products due to its ability to improve hair texture and shine.

In agriculture, the application of PGA as a soil amendment has gained traction. It helps improve water retention and nutrient absorption in plants, thereby increasing agricultural productivity. Therefore, the demand for PGA in both the cosmetic and agricultural sectors continues to grow, driving factories to ramp up production capabilities.

Future Prospects

Looking ahead, ordinary polyglutamic acid factories are poised for further growth and innovation. Advances in biotechnology may lead to more efficient production methods and the discovery of new applications for PGA. As consumer trends shift towards sustainable and eco-friendly products, the demand for biopolymers like PGA is expected to rise.

Furthermore, ongoing research into the health benefits of polyglutamic acid may lead to its incorporation in nutraceuticals and functional foods. This presents a myriad of opportunities for manufacturers to explore uncharted territories and cater to an ever-evolving market.

In conclusion, ordinary polyglutamic acid factories represent a nexus of innovation and sustainability. As these factories continue to produce this versatile biopolymer, they contribute to advancements in various industries while meeting the increasing demand for natural and effective ingredients in both cosmetics and agriculture. The future of PGA appears promising as the world leans toward sustainability and holistic solutions for everyday challenges.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025