High-performance set retarder for calcium sulfate(gypsum) Retarder - HN150L

Product description:

HN150L is a high-performance set retarder for Calcium Sulphate or Gypsum based binding materials.

HN150L has no affect at strength of gypsum products

HN150L is environment-friendly and free formaldehyde.

HN150L has the characteristics of efficient at low dosages, increase of workability time of plasters or gypsum, compatible to a variety of calcium sulphate or gypsum binder types and to other additives.

Mainly application areas:

Fabrication of gypsum boards (also: plasterboards, wallboards), partition panels, ceiling tiles

Fabrication of gypsum fibreboards, building elements, blocks

Manufacture of building plaster, render, stucco, bonding/filling compound, molding plaster, dental & medical plaster

Production of floor screeds, self-levelling screeds and underlayments based on calcium sulphate binders and ternary compounds.

Initial setting time at gypsum:

|

dosage(g/t) |

SK200L |

HN150L |

|

0 |

15min |

15min |

|

20g |

25min |

24min |

|

40g |

32min |

31min |

|

60g |

39min |

37min |

|

80g |

46min |

47min |

|

100g |

52min |

53min |

Physical properties:

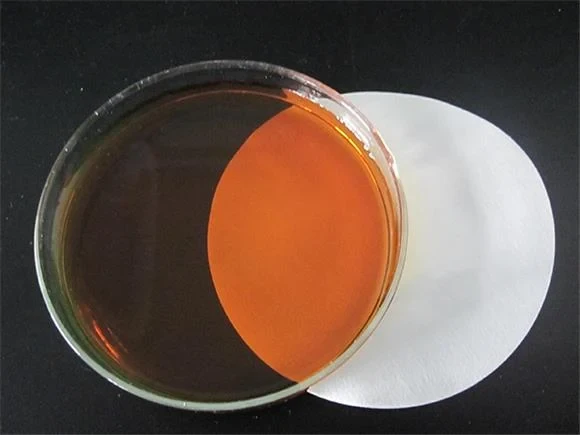

Amber colour Clear Solution, Active matter: ≥ 50%, Density@20℃): ≥ 1.10 g.cm-3, pH Value: 3.0-7.0.

Package:

Packed in 200L drum; or 1000L IBC Tanker; or as customers’ request

Shipping classification:

Non-hazardous for road, sea or air transport.

1. Formula optimization

Based on the existing product formula, optimize the mix proportion, analyze the compatibility of additives, and add additives to different gypsum systems

Selection, etc., to improve product performance; Or reduce product costs on the basis of existing performance, such as gypsum self leveling, plastering gypsum, etc.

2. Product improvement

Provide improvement suggestions for the problems existing in gypsum products, such as enhancing the self leveling of gypsum and controlling cracking.

3. Product Upgrade

Upgrade existing products to enhance competitiveness. If the weight of lightweight plastering gypsum is reduced to 160, 180; Conversion of formula for self leveling gypsum products with and without sand molds; Optimization and upgrading of crack resistant, waterproof, and mold resistant gypsum mortar products.

4. Product development

Provide product development services for major and strategic customers, such as: ① Development of insulation type plastering gypsum products (with a unit weight of less than 500); ② Development of gypsum based self leveling heating and backfilling products; ③ Development of ceramic tile adhesive products; ④ Development of phosphogypsum related products;

⑤ Development of phosphogypsum type II anhydrous gypsum/natural anhydrous gypsum products.

5. Application Technology Solutions

① Gypsum products have unstable solidification and plastic cracking; ② Large area cracking of gypsum self leveling products and insulation and sound insulation structures; ③

Technical guidance for gypsum self leveling construction; ④ Appearance quality issues such as alkalinity, mold, and oil stains in phosphogypsum products; ⑤ Product optimization and construction quality control in different seasonal environments; ⑥ Product quality control under different gypsum types, impurity environments, and pH conditions.