News

stu . 06, 2024 01:06 Back to list

Chelant Use in Boiler Feed Water Treatment for Enhanced Efficiency and Performance

The Role of Chelants in Boiler Feed Water Treatment

Boilers play a crucial role in various industrial processes, generating steam for power generation, heating, and other critical applications. However, the efficiency and longevity of a boiler system are significantly influenced by the quality of the feed water used. One effective way to ensure optimal feed water quality is through the use of chelants—chemical compounds that form stable complexes with metal ions.

Understanding Chelants

Chelants, also known as chelating agents or sequestrants, are molecules that can bind to metal ions in solution. This binding prevents the metals from participating in undesirable chemical reactions, thereby mitigating potential damage or inefficiencies in boiler systems. Commonly found in various industries, chelants are particularly valuable in boiler feed water treatment due to their ability to control boiler scale and corrosion.

Importance of Feed Water Quality

The quality of boiler feed water directly impacts the efficiency, reliability, and longevity of the boiler. Poor quality water can lead to scaling, corrosion, and foaming, all of which significantly impair operational efficiency. Scale formation, primarily due to calcium and magnesium ions, can create insulating layers on heat exchange surfaces, leading to overheating and potential failure. Similarly, the presence of dissolved oxygen and carbon dioxide can catalyze corrosion, further compromising the integrity of the boiler.

Mechanism of Action

Chelants work by binding to harmful metal ions, thus preventing their deposition and potential harmful effects. For instance, in the case of calcium and magnesium, chelants such as EDTA (Ethylenediaminetetraacetic acid) can form stable complexes that remain soluble in water, effectively keeping these ions in solution and preventing scale formation. Moreover, chelants can also stabilize other trace metals that might lead to corrosion, such as iron and copper, by sequestering them before they can react with the metal surfaces of the boiler.

Types of Chelants Used

Various chelating agents can be used for treating boiler feed water, each with distinct properties and effectiveness. Some commonly employed chelants include

1. EDTA (Ethylenediaminetetraacetic acid) A widely used chelating agent, EDTA is effective in binding divalent and trivalent metal ions, thus preventing their precipitation.

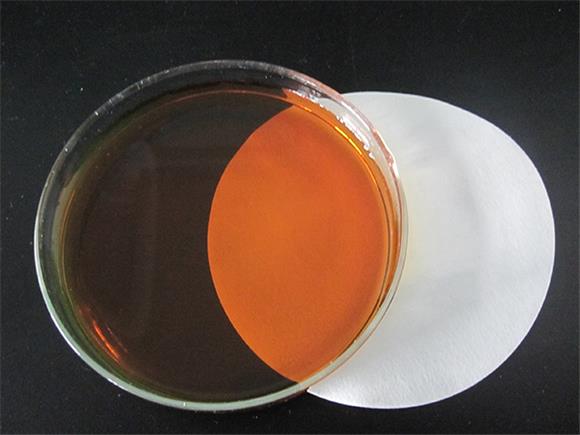

chelant in boiler feed water factory

2. NTA (Nitrilotriacetic acid) This is an alternative to EDTA, particularly in situations where biodegradability is a concern. NTA effectively sequesters metal ions but with a lower environmental impact.

4. Phosphonates These are particularly effective in controlling scale formation, working well in conjunction with other treatment chemicals to enhance overall boiler performance.

Benefits of Using Chelants

Incorporating chelants into boiler feed water treatment offers several benefits

- Scale Prevention By effectively binding calcium and magnesium ions, chelants minimize scaling within the boiler system, enhancing heat transfer efficiency.

- Corrosion Control Chelants reduce the availability of corrosion-inducing metal ions, thereby protecting boiler components and extending their lifespan.

- Operational Efficiency Improved water quality translates into less downtime for maintenance and repairs, leading to enhanced operational productivity and cost-effectiveness.

- Environmentally Considerate Many modern chelants are designed to be biodegradable and less harmful to the environment compared to traditional treatment agents.

Conclusion

Chelants play a pivotal role in maintaining the quality of boiler feed water, which is integral to the operational integrity of boiler systems. By effectively binding and removing harmful metal ions, chelants significantly enhance boiler efficiency, control scale and corrosion, and prolong the life of boiler components. As industries continue to seek sustainable and efficient solutions, the use of chelants in boiler feed water treatment stands out as a proven method to ensure both operational success and environmental responsibility. Thus, investing in advanced chelation technology is a step toward improved resource management and industrial productivity.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025