News

dec . 03, 2024 11:47 Back to list

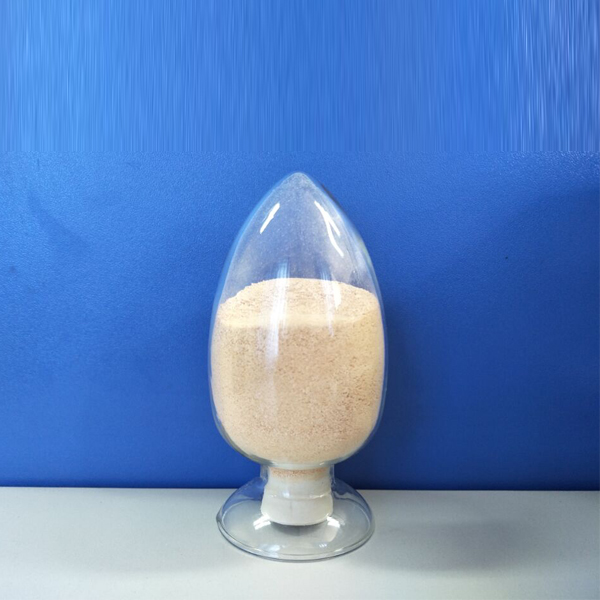

oem aluminum chelation

Understanding OEM Aluminum Chelation A Comprehensive Overview

In recent years, the use of aluminum in various industrial applications has gained significant attention due to its unique properties—such as lightweight, strength, and resistance to corrosion. However, the growing environmental concerns and health implications related to aluminum exposure have spurred innovations in its handling and application. One of the emerging solutions is the concept of OEM (Original Equipment Manufacturer) aluminum chelation. This article delves into the intricacies of aluminum chelation, its importance in the OEM industry, and its potential benefits.

What is Aluminum Chelation?

Aluminum chelation refers to the process where chelating agents bind to aluminum ions, forming a stable complex. Chelating agents are organic compounds that can attach to metal ions, effectively “locking” them in place. This process is crucial in various applications, including water treatment, pharmaceuticals, and even agricultural products, to prevent aluminum toxicity and enhance the bioavailability of certain nutrients.

In an OEM context, aluminum chelation is particularly relevant for manufacturers that produce aluminum-based products or use aluminum in their designs. By integrating chelation techniques, these companies can improve product performance while addressing safety and environmental regulations.

Importance of Aluminum Chelation in OEM

1. Enhanced Safety One of the primary concerns with aluminum is its potential neurotoxicity. By utilizing chelation techniques, manufacturers can mitigate the risks associated with aluminum exposure, ensuring that their products are safer for consumers. This is particularly important in industries such as food packaging, medical devices, and consumer electronics.

2. Improved Product Stability Aluminum chelation can enhance the stability of products by preventing unwanted reactions between aluminum and other compounds. For example, in pharmaceuticals, chelation can help ensure that active ingredients remain effective over time, avoiding degradation caused by interaction with aluminum.

3. Environmental Considerations In an era where sustainability is critical, OEMs are under pressure to minimize their ecological footprint. Aluminum chelation can help reduce aluminum leaching into the environment, thus contributing to cleaner production practices. Additionally, by improving the efficacy of aluminum applications, manufacturers can reduce the overall demand for raw materials.

oem aluminum chelation

4. Regulatory Compliance As governments and regulatory bodies implement stricter guidelines regarding material safety, the ability to demonstrate safe handling of aluminum becomes paramount. OEMs employing aluminum chelation can better comply with regulations, thus avoiding potential penalties and enhancing their market reputation.

The Process of OEM Aluminum Chelation

The process typically involves several key steps

1. Selection of Chelating Agents The first step is the identification of appropriate chelating agents. These agents must possess the capability to effectively bind with aluminum while being non-toxic and environmentally friendly.

2. Formulation Development Once suitable agents are chosen, OEMs develop formulations that blend these chelators with aluminum materials. This step requires meticulous attention to ensure the right concentrations and combinations are used for optimal effectiveness.

3. Testing and Quality Assurance Before the chelated aluminum products are released into the market, they undergo rigorous testing to ascertain their safety, efficacy, and compliance with industry standards. This not only protects consumers but also fortifies the manufacturer’s credibility.

4. Market Launch and Feedback Finally, the products are launched in the market with thorough documentation regarding their safety and environmental impact. Continuous feedback loops from user experiences can guide future development and improvement of the chelation process.

Conclusion

The integration of OEM aluminum chelation represents a significant advancement in the responsible use of aluminum across various industries. By focusing on safety, stability, and environmental sustainability, manufacturers can not only meet regulatory demands but also enhance their product offerings and protect consumers from potential risks associated with aluminum use. As awareness grows and technology advances, the potential for aluminum chelation to revolutionize product applications will only increase, paving the way for a safer and more sustainable industrial future.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025