News

des . 04, 2024 22:19 Back to list

edta type chelating agent factory

Understanding EDTA-Type Chelating Agents and Their Manufacturing

Chelating agents play a crucial role in various industrial and environmental applications, and among them, EDTA (ethylenediaminetetraacetic acid) stands out as one of the most widely used. EDTA is a synthetic compound that binds metal ions through coordinated covalent bonds, forming stable chelate complexes. This characteristic makes EDTA invaluable in fields ranging from agriculture to pharmaceuticals, making its production and supply a vital component of modern chemical manufacturing.

The Chemistry of EDTA

EDTA is a polyaminocarboxylic acid with the chemical formula C10H16N2O8. Its unique structure allows it to effectively trap metal ions, preventing them from participating in unwanted reactions. This property is particularly beneficial in water treatment, where EDTA can sequester harmful metals like lead, mercury, and cadmium, thus reducing their toxicity. In agriculture, EDTA forms stable complexes with essential nutrient metals, such as iron and zinc, ensuring their availability for plant uptake.

Applications of EDTA Chelating Agents

1. Water Treatment EDTA is extensively used in water treatment processes to remove heavy metals and improve water quality. It effectively chelates metal contaminants, making it easier to separate them from water sources.

2. Agriculture In the agricultural sector, EDTA chelating agents are often used in fertilizers to enhance the bioavailability of micronutrients. This leads to better crop yields and healthier plants since these nutrients are crucial for plant growth.

3. Pharmaceuticals In the pharmaceutical industry, EDTA is employed as a stabilizing agent in various formulations, particularly those involving metal ions. It also finds use in medical treatments for heavy metal poisoning, where it helps remove toxic metals from the body.

4. Industrial Applications Many industrial processes utilize EDTA to control metal ions that could interfere with operations. This includes applications in textiles, cosmetics, and food processing, where maintaining optimal conditions is essential for product quality.

edta type chelating agent factory

Manufacturing Process of EDTA

The manufacturing of EDTA involves several key steps, ensuring that the final product is of high purity and suitable for various applications. Here’s an overview of the typical EDTA production process

1. Raw Material Procurement The primary raw materials for producing EDTA are ethylenediamine and chloroacetic acid. The quality of these raw materials significantly impacts the final product.

2. Synthesis Reaction The production of EDTA typically involves a multi-step chemical reaction where ethylenediamine is reacted with chloroacetic acid. The reaction conditions, including temperature and pH, are meticulously controlled to ensure optimal yields.

3. Purification After synthesis, the crude EDTA is subjected to various purification methods, including crystallization and filtration, to eliminate impurities and achieve the desired product specifications.

4. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. This includes analytical testing to confirm the purity and effectiveness of the EDTA produced.

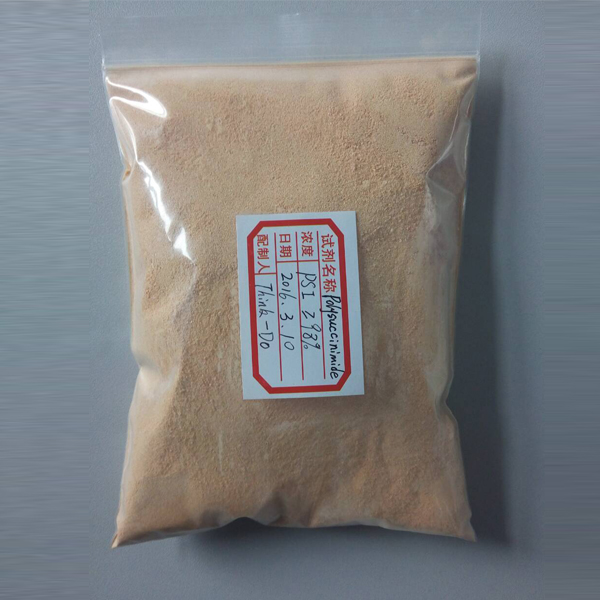

5. Packaging and Distribution Once the product meets the required standards, it is packaged appropriately for distribution. The packaging ensures that the EDTA remains stable and uncontaminated during transportation.

Conclusion

EDTA-type chelating agents are indispensable in numerous industries due to their ability to form stable complexes with metal ions. Understanding the manufacturing process and applications of EDTA helps highlight its significance in both industrial and environmental contexts. As industries strive for sustainability and efficiency, the role of chelating agents like EDTA will continue to be vital in addressing metal contamination issues and enhancing product quality. The continuous development of manufacturing technologies will ensure that these agents remain readily available and effective for future needs.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025