News

nóv . 23, 2024 07:59 Back to list

polyglutamic acid production price

Production Price of Polyglutamic Acid An Overview

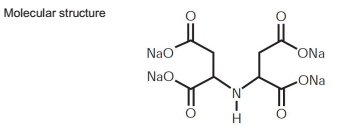

Polyglutamic acid (PGA) is a biopolymer that has garnered significant attention in various industries due to its versatile applications. Derived from glutamic acid, a naturally occurring amino acid, PGA is produced by certain bacteria like Bacillus subtilis through a fermentation process. The result is a biodegradable and non-toxic polymer that has found uses in agriculture, food processing, cosmetics, pharmaceuticals, and environmental applications. However, understanding the production price of polyglutamic acid requires an examination of several key factors involved in its manufacturing process.

Production Process

The production of polyglutamic acid primarily involves fermentation, although alternative chemical synthesis routes exist. Fermentation is conducted using microbial strains that metabolize carbon sources, typically sugars, to produce PGA. This process includes several stages inoculum preparation, fermentation, and downstream processing, which involves purification and concentration of the product. Each stage incurs costs, including raw materials, equipment, labor, and energy.

Raw Material Costs

One of the most significant contributors to the overall production cost of polyglutamic acid is the price of raw materials. The primary feedstock for PGA production is carbon sources such as glucose or sucrose, which vary in price depending on market demand and availability. Additionally, the cost of nitrogen sources, such as ammonium salts or yeast extract, can fluctuate and affect overall production costs. As the global demand for natural and biodegradable products rises, securing affordable and sustainable raw materials remains a critical challenge.

polyglutamic acid production price

Scale of Production

The scale at which polyglutamic acid is produced significantly impacts its price. Larger scale operations can benefit from economies of scale, leading to reduced costs per unit of PGA produced. Conversely, smaller production facilities may face higher costs due to inefficiencies and the inability to spread fixed costs over larger volumes. As companies seek to meet rising demand, scaling up production capacities can lead to more competitive pricing in the marketplace.

Technological Advancements

Technological innovations also play a critical role in influencing the production price of polyglutamic acid. Advances in fermentation technology, strain improvement, and optimization of growth conditions can enhance yield and reduce production time. Investing in research and development can lead to more efficient processes, thereby lowering costs associated with labor and raw materials. Consequently, companies that embrace technological advancements may gain a competitive edge in pricing.

Conclusion

The production price of polyglutamic acid is influenced by a complex interplay of raw material costs, production scale, and technological advancements. As industries increasingly recognize the value of environmentally friendly biopolymers, understanding the factors affecting PGA pricing will be crucial for manufacturers aiming to capitalize on its diverse applications. By optimizing production processes and securing cost-effective raw materials, companies can not only enhance their profitability but also contribute to a more sustainable future. As the market for polyglutamic acid continues to grow, ongoing efforts to reduce production costs will be essential in meeting global demand while maintaining economic viability.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025