News

9월 . 23, 2024 22:32 Back to list

Improving Lead Manufacturing with Advanced Chelating Agents for Enhanced Safety and Efficiency

The Role of Chelating Agents in Lead Factories

Chelating agents are substances that can form multiple bonds with a single metal ion, effectively grabbing and removing it from a solution. In the context of lead factories, these agents play a crucial role in both the management of lead contamination and the enhancement of lead recovery processes. With increasing environmental concerns and regulatory pressures surrounding the use of lead, the application of chelating agents has become an essential strategy for sustainable operations in lead manufacturing.

The Role of Chelating Agents in Lead Factories

Moreover, chelating agents can improve the efficiency of lead recovery during recycling processes. In lead smelting operations, ores often contain a mix of metals, and separating lead from these materials can be challenging. By using chelating agents, manufacturers can selectively bind to lead ions, thus enhancing their extraction from other metals. This selective binding not only increases the yield of lead but also reduces the overall consumption of energy and resources in the recycling process.

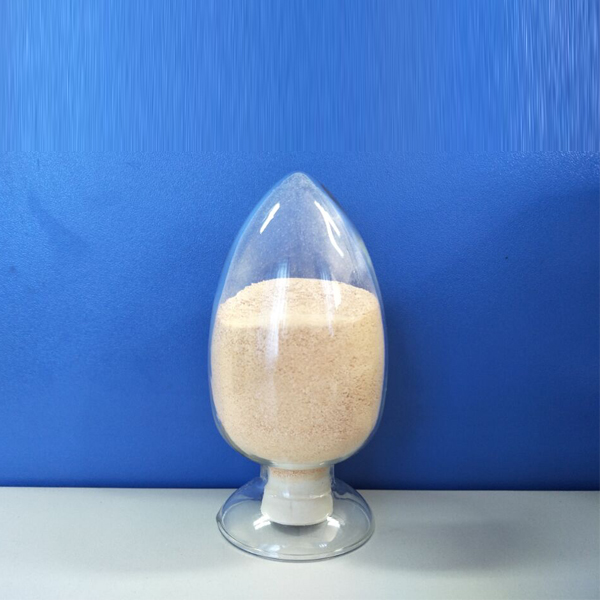

chelating agent lead factory

In addition to their application in lead recovery and wastewater treatment, chelating agents also play a role in the prevention of lead corrosion in industrial equipment. Lead can be prone to corrosion when exposed to certain conditions, which can lead to operational inefficiencies and increased maintenance costs. Chelating agents can form complexes with lead ions, stabilizing them and reducing their reactivity. This helps in extending the lifespan of machinery and ensures smoother operations within the factory environment.

Despite their advantages, the use of chelating agents does not come without challenges. The environmental implications of some chelating substances, particularly those that are not biodegradable, raise concerns about their long-term effects. Consequently, research is ongoing to find more eco-friendly alternatives that can serve similar purposes without posing risks to the environment.

In conclusion, chelating agents are indispensable in lead factories, providing effective solutions for wastewater treatment, lead recovery, and equipment maintenance. Their ability to bind toxic lead ions not only helps in mitigating environmental impacts but also enhances operational efficiency. As the lead industry continues to evolve, the development of safe and sustainable chelating agents will be paramount in ensuring responsible manufacturing practices. The future of lead production will likely depend on integrating these advanced materials into a broader strategy that prioritizes environmental stewardship and resource conservation.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025