News

3월 . 04, 2025 09:58 Back to list

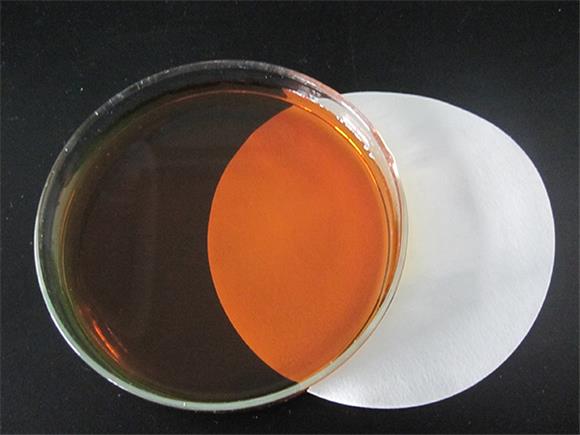

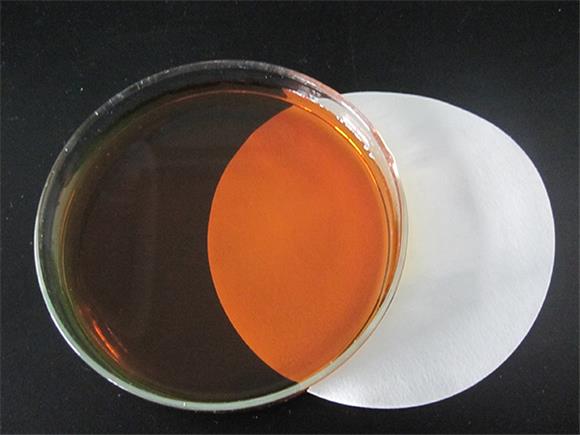

Iminodisuccinic acid sodium salt(IDS-Na)

Optimizing oem zinc chelating agents can dramatically influence the efficacy and longevity of various industrial and consumer products. Throughout years of experience in the chemical manufacturing sector, it has become evident that the right choice of zinc chelating agent is crucial for achieving optimal product performance and stability.

Industry authority figures also highlight the growing demand for eco-friendly and sustainable chelating agents in alignment with global environmental standards. Forward-thinking companies are investing in research and development to create biodegradable and non-toxic zinc chelating solutions. These innovations support sustainable manufacturing practices and cater to increasing consumer demand for green products. Trust in zinc chelating agents is built through stringent quality control and third-party testing, ensuring every batch meets precise specifications. This transparency builds long-term relationships with partners and consumers who seek reliable, high-quality chemical solutions. Moreover, OEM manufacturers often look for chelating agents that offer compatibility with a wide range of substrates, from textiles and plastics to pharmaceuticals and cosmetics. This versatility increases the value of the agent, making it a crucial component across various industries. In conclusion, the selection and application of OEM zinc chelating agents should be approached with experience, expertise, authority, and trust. By focusing on these four pillars, manufacturers can enhance product quality, comply with regulatory standards, and meet the evolving demands of the modern market. Each carefully chosen agent not only boosts product performance but also contributes to a brand’s reputation, underscoring the importance of informed decision-making in product formulation.

Industry authority figures also highlight the growing demand for eco-friendly and sustainable chelating agents in alignment with global environmental standards. Forward-thinking companies are investing in research and development to create biodegradable and non-toxic zinc chelating solutions. These innovations support sustainable manufacturing practices and cater to increasing consumer demand for green products. Trust in zinc chelating agents is built through stringent quality control and third-party testing, ensuring every batch meets precise specifications. This transparency builds long-term relationships with partners and consumers who seek reliable, high-quality chemical solutions. Moreover, OEM manufacturers often look for chelating agents that offer compatibility with a wide range of substrates, from textiles and plastics to pharmaceuticals and cosmetics. This versatility increases the value of the agent, making it a crucial component across various industries. In conclusion, the selection and application of OEM zinc chelating agents should be approached with experience, expertise, authority, and trust. By focusing on these four pillars, manufacturers can enhance product quality, comply with regulatory standards, and meet the evolving demands of the modern market. Each carefully chosen agent not only boosts product performance but also contributes to a brand’s reputation, underscoring the importance of informed decision-making in product formulation.

Latest news

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025