News

Oct . 17, 2024 12:31 Back to list

Cost Analysis of Calcium Sulfate Binder Retarder for Construction Applications

The Role and Cost of Retarders in Calcium Sulfate Binder Applications

Calcium sulfate binders, commonly known as gypsum-based products, are widely used in the construction industry for applications such as plaster, wallboard, and cement. One of the key challenges in utilizing calcium sulfate binders is managing the setting time during application. This is where retarders come into play. Retarders are chemical additives that slow down the hydration process, allowing for extended working times. This article explores the significance of retarders in calcium sulfate binders, alongside a discussion on pricing and market considerations.

Importance of Retarders

The primary function of retarders in calcium sulfate binder formulations is to regulate the setting time during application. Gypsum's natural setting time is relatively quick; thus, various conditions such as temperature, humidity, and mix proportions can significantly affect its workability. By incorporating retarders, construction professionals can achieve more manageable setting times, making it easier to work with large areas, intricate designs, or even complex formulations.

Retarders are particularly crucial in hot weather conditions, where the rapid evaporation of water can lead to premature setting of the binder. Additionally, they improve the overall finish of the surface by allowing more time for adequate mixing, application, and finishing techniques. As construction projects often operate on tight schedules, the ability to extend working time without compromising the quality of the final product is invaluable.

Types of Retarders

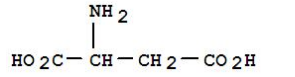

There are several types of retarders used in combination with calcium sulfate binders. Common retarders include hydroxycarboxylic acids, lignosulfonates, and various phosphates. Each type has its unique mechanism of action and may vary in effectiveness depending on the specific formulation of the binder and the environmental conditions.

retarder for calcium sulfate binder price

Hydroxycarboxylic acids, for example, work by interacting with the calcium ions in the gypsum, creating a complex that slows down the setting reaction. Lignosulfonates act as a dispersing agent, which can also prolong the setting time while improving workability. Phosphate-based retarders are particularly effective in mitigating the effects of high temperatures and reducing the rate of hydration, ensuring that the product remains usable for extended periods.

Market Price Considerations

The price of retarders for calcium sulfate binders can vary significantly based on several factors, including the type of retarder used, the quantity purchased, and market fluctuations. Generally, retarders are sold by manufacturers either as standalone products or integrated into specific binder formulations.

Market prices are influenced by raw material costs, production capabilities, and regional demand. For instance, in regions where gypsum-based products are in high demand, the pricing of retarders may increase correspondingly. On the other hand, the advancement of production techniques and the availability of alternatives can help stabilize or even reduce costs.

For construction companies and contractors, understanding the cost implications of using retarders is critical. While it may seem economical to use lower-cost retarders, the long-term effectiveness and potential impact on product quality should be considered. Investing in high-quality retarders can lead to better workability and finish, resulting in fewer rework costs and higher user satisfaction.

Conclusion

In conclusion, retarders play a vital role in the effectiveness and application of calcium sulfate binders in the construction industry. Their ability to extend working time while maintaining quality makes them essential additives in many formulations. As with any construction-related material, understanding the costs associated with retarders can help ensure the successful execution of projects while optimizing budgetary constraints. By choosing the right type of retarder, construction professionals can enhance their workflows, improve the finished product, and achieve lasting results in their building endeavors.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025