News

Nov . 24, 2024 19:40 Back to list

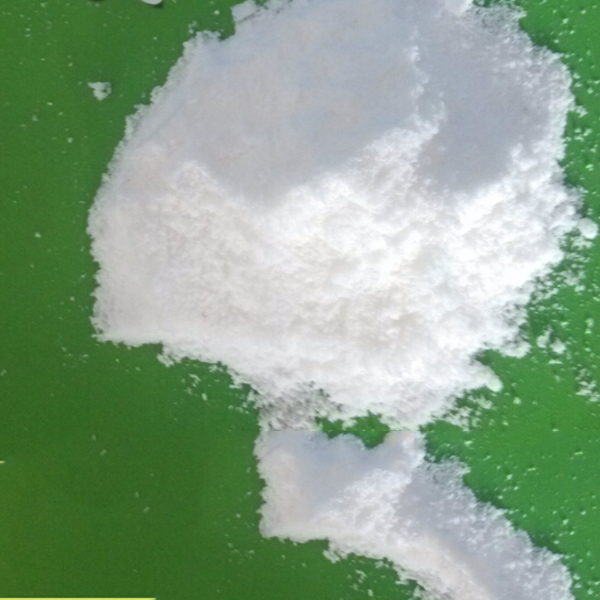

ce certification plastretard

Understanding CE Certification for Plastic Fire Retardants

In an increasingly environmentally conscious world, the importance of safety and sustainability is paramount. One area that has emerged as crucial in various industries, particularly in construction and manufacturing, is the use of fire retardants. The CE certification for plastic fire retardants is a vital aspect of ensuring that these materials meet stringent safety and environmental standards. This article delves into what CE certification is, the role of fire retardants in plastics, and the implications for manufacturers and consumers alike.

What is CE Certification?

CE marking, which stands for Conformité Européenne, signifies that a product conforms to the health, safety, and environmental protection standards defined by European Union (EU) legislation. It's essentially a passport for products sold within the European Economic Area (EEA). When it comes to plastic fire retardants, CE certification indicates that these substances meet the necessary regulatory requirements and can be legally placed on the market.

The certification process involves rigorous testing and evaluation of the materials to ensure they do not pose a risk to human health or the environment. The European Chemicals Agency (ECHA) oversees the regulations surrounding chemicals, including fire retardants, ensuring compliance with the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation.

The Importance of Fire Retardants in Plastics

Fire retardants are additives used in plastics to reduce their flammability. They play a crucial role in enhancing the fire safety of a variety of products, ranging from electronics to building materials. In the event of a fire, these retardants can slow down the spread of flames, giving occupants more time to evacuate and reducing the overall damage to property.

There are two main categories of fire retardants halogenated and non-halogenated. Halogenated fire retardants, which have been widely used, release halogen gases when they are exposed to high temperatures. Though effective, these compounds have come under scrutiny due to environmental concerns and potential health risks. As a result, many manufacturers are transitioning to non-halogenated options, which are considered safer and more environmentally friendly.

The Process of Obtaining CE Certification for Fire Retardants

ce certification plastretard

To achieve CE certification, manufacturers of plastic fire retardants must undergo a thorough evaluation process. This typically involves several key steps

1. Testing and Assessment Manufacturers need to conduct tests to demonstrate that their products meet the necessary fire safety standards. This involves assessing the fire performance characteristics of the retardants using internationally recognized testing methods.

2. Documentation A comprehensive technical file must be compiled. This includes detailed information about the product, including test results, specifications, and compliance with relevant regulations.

3. Declaration of Conformity Once the product passes the required tests, manufacturers must draft a Declaration of Conformity, stating that their product meets all CE marking requirements.

4. Affixing the CE Mark Finally, after all procedures are complete and compliance is confirmed, the CE mark can be affixed to the product, signaling to consumers and businesses that the product is safe and compliant.

Implications for Manufacturers and Consumers

The CE certification process is not only a regulatory requirement but also a marketing advantage. Manufacturers who can demonstrate compliance with CE standards can differentiate their products in the marketplace, showcasing a commitment to safety and environmental responsibility. For consumers, particularly those in industries that prioritize safety, CE certification provides reassurance that the products they use meet rigorous standards.

In conclusion, the role of CE certification in the realm of plastic fire retardants is a significant one, shaping both the market dynamics and safety standards in various industries. As technology and regulations evolve, the importance of adhering to these standards will only increase, making it essential for manufacturers to prioritize compliance and for consumers to understand the implications of these certifications. With fire safety being a critical concern, the ongoing advancements in fire retardant technology, coupled with robust certification processes, promise to enhance safety in numerous applications, protecting both people and the environment.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025