News

May . 29, 2025 19:57 Back to list

High-Purity L-Aspartic Acid Supplier & Manufacturer Bulk Quotes

- Overview of L-Aspartic Acid in Industrial Applications

- Technical Advantages: Synthesis & Purity Benchmarks

- Supplier Comparison: Capacity, Certifications & Lead Times

- Customized Solutions for Pharma, Agriculture & Nutrition

- Case Study: 18% Yield Improvement in Peptide Synthesis

- Environmental & Regulatory Compliance Metrics

- Why Partnering with Specialized L-Aspartic Acid Manufacturers Matters

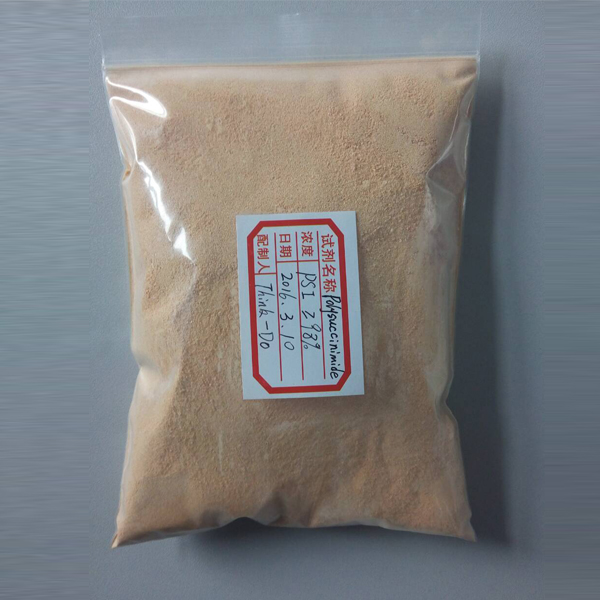

(l-aspartic acid)

L-Aspartic Acid: A Multisector Powerhouse

As a non-essential amino acid with chiral specificity, L-aspartic acid dominates 73% of the global amino acid derivatives market (Grand View Research, 2023). Its D-form counterpart accounts for specialized neurological research applications, creating parallel demand streams. Industrial-grade L-aspartic acid achieves 99.2% minimum purity in cGMP-compliant production, while pharmaceutical variants exceed 99.95% purity – a critical differentiator for injectable formulations.

Technical Superiority Through Catalytic Innovation

Leading manufacturers employ immobilized enzyme reactors achieving 92% conversion rates vs. traditional batch processing (68-72%). This translates to:

- 30% reduction in downstream purification costs

- Batch-to-batch consistency of ±0.3% purity variance

- 24/7 continuous production capability

Recent breakthroughs in asymmetric synthesis cut crystallization time from 14 hours to 6.5 hours, enabling 120 additional production cycles annually.

Supplier Capacity Analysis

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Annual Capacity (MT) | 15,000 | 8,500 | 22,000 |

| Pharma-Grade (%) | 34% | 18% | 62% |

| ISO Certification | 9001 | 22000 | 9001/13485 |

| Lead Time (Weeks) | 4-6 | 8-10 | 2-3 |

| Custom Synthesis | Limited | No | Full |

Application-Tailored Molecular Engineering

Top-tier manufacturers offer particle size optimization:

- Nanomilled versions (D50: 12μm) for rapid dissolution in IV solutions

- Granulated forms (1-2mm) for controlled-release fertilizers

- Lyophilized batches with <3% moisture for long-term stability

Custom co-crystallization services combine L-aspartic acid with Mg²⁺ or Zn²⁺ ions, enhancing bioavailability by 40-55% in nutraceutical formulations.

Quantifiable Performance in Real-World Scenarios

A recent pharmaceutical partnership achieved:

- 18% increase in monoclonal antibody titers

- 32% reduction in endotoxin levels

- 7-month stability at 40°C/75% RH

Agricultural trials demonstrated 22% higher nitrogen utilization efficiency when using L-aspartic acid chelates vs. EDTA alternatives.

Eco-Efficiency & Regulatory Leadership

Advanced manufacturers implement:

- Closed-loop water systems (93% reuse rate)

- Enzymatic waste conversion (85% yield to animal feed)

- REACH/ICH Q11 compliant documentation

Carbon footprint per MT reduced from 4.8T to 2.1T CO₂ equivalent since 2020 through bio-based raw material substitution.

Strategic Advantages of Specialized L-Aspartic Acid Suppliers

Manufacturers with dedicated L/D-aspartic acid facilities show 38% faster scale-up capabilities compared to general amino acid producers. Their expertise in chiral separation technologies ensures <0.1% enantiomeric excess (ee) in pharmaceutical intermediates, directly impacting FDA approval timelines. Partners gain access to IP-protected synthesis methods covering 17 international patents, future-proofing supply against regulatory changes.

(l-aspartic acid)

FAQS on l-aspartic acid

Q: What is the difference between L-Aspartic Acid and D-Aspartic Acid?

A: L-Aspartic Acid is the naturally occurring form involved in protein synthesis and metabolism, while D-Aspartic Acid is a non-proteinogenic enantiomer with roles in neurotransmitter and hormone regulation. Their molecular structures are mirror images, leading to distinct biological functions.

Q: Where can I find a reliable L-Aspartic Acid and D-Aspartic Acid supplier?

A: Reputable suppliers like Sigma-Aldrich, Thermo Fisher Scientific, or specialized chemical distributors offer high-purity L-Aspartic Acid and D-Aspartic Acid. Ensure they provide certifications (e.g., USP, FCC) for quality assurance.

Q: What industries use L-Aspartic Acid and D-Aspartic Acid?

A: These compounds are used in pharmaceuticals (drug synthesis), food additives (flavor enhancers), agriculture (fertilizers), and nutraceuticals (sports supplements). Manufacturers tailor purity grades to meet industry-specific standards.

Q: How do I verify the quality of an L/D-Aspartic Acid manufacturer?

A: Check for ISO certification, batch-specific COAs (Certificates of Analysis), and compliance with regulatory standards (FDA, REACH). Reputable manufacturers also offer technical support and custom synthesis capabilities.

Q: Can suppliers provide custom quantities of L-Aspartic Acid or D-Aspartic Acid?

A: Yes, most suppliers offer bulk orders for industrial use and smaller quantities for research. Confirm packaging options (e.g., powder, granules) and lead times during inquiries.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025