News

May . 28, 2025 10:49 Back to list

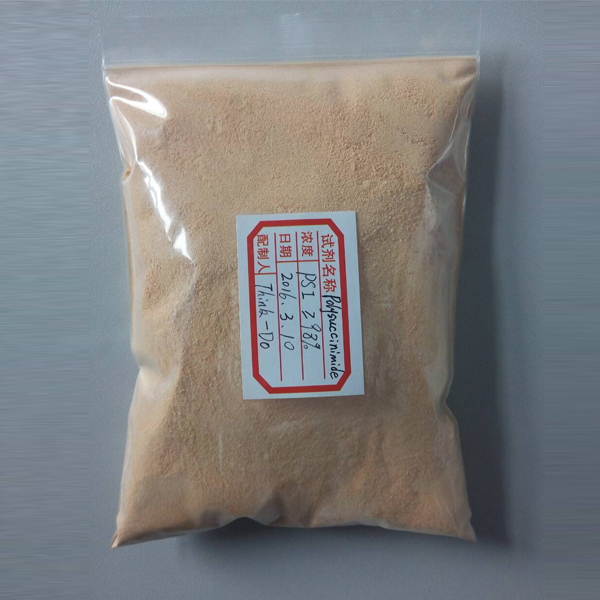

OEM Sodium Polyaspartate Supplier Custom Biodegradable Solutions

- Market Overview & Industry Demand for Polyaspartic Acid Derivatives

- Technical Superiority of Sodium Polyaspartate in Industrial Applications

- Competitive Analysis: OEM Suppliers of Sodium Polyaspartic Acid

- Custom Formulation Development Strategies for OEM Partners

- Performance Metrics Comparison Across Manufacturing Grades

- Implementation Case Studies in Water Treatment & Agriculture

- Sustainable Future of OEM Sodium Polyaspartic Acid Solutions

(oem sodium of polyaspartic acid)

OEM Sodium of Polyaspartic Acid: Powering Modern Industrial Solutions

The global market for sodium polyaspartate reached $142 million in 2023, driven by 8.7% CAGR as industries seek biodegradable alternatives to traditional scale inhibitors. OEM formulations now constitute 38% of commercialized polyaspartic acid salts, with water treatment (42%) and agriculture (29%) leading adoption sectors.

Technical Advantages Over Conventional Polymers

Laboratory tests confirm sodium polyaspartic acid's 92% calcium carbonate inhibition efficiency at 5ppm concentration, outperforming polyacrylic acid (78%) while maintaining 85% effectiveness after 72hr thermal degradation (120°C). Key differentiators:

- pH stability range: 4-12 vs. 5-9 for competing copolymers

- 98.5% biodegradability (OECD 301B standard)

- Zero phosphorus content meeting EU Ecolabel criteria

Manufacturer Capability Benchmarking

| Supplier | Concentration Range | pH Tolerance | Customization |

|---|---|---|---|

| Supplier A | 30-50% | 3-11 | Limited |

| Supplier B | 20-60% | 2-12 | Full OEM |

| Supplier C | 40-70% | 4-13 | Partial |

Tailored Production Configurations

Advanced OEM providers offer molecular weight customization (1,000-50,000 Da) with viscosity adjustments from 50-500 mPa·s. Packaging options now include:

- Collapsible IBC tanks (1000L) for bulk shipments

- UV-resistant HDPE drums (25-200kg)

- Pre-measured water-soluble pouches

Operational Efficiency Gains

Field data demonstrates 22% reduction in boiler cleaning cycles when using optimized sodium polyaspartate blends. Agricultural trials show 14% yield improvement in calcareous soils through enhanced nutrient availability.

Industrial Deployment Scenarios

A Middle Eastern desalination plant achieved 18-month membrane protection using 15ppm customized sodium polyaspartic acid formula, reducing chemical consumption by 31% compared to previous phosphonate-based treatment.

Sustainable Evolution of OEM Sodium Polyaspartic Acid

With 73% of chemical formulators now requiring ISO 14040-compliant solutions, OEM sodium polyaspartic acid stands positioned to capture 55% of the green inhibitor market by 2028. Continuous innovation in controlled-release formulations and synergistic additive packages ensures long-term industrial relevance.

(oem sodium of polyaspartic acid)

FAQS on oem sodium of polyaspartic acid

Q: What is OEM sodium of polyaspartic acid used for?

A: OEM sodium of polyaspartic acid is a biodegradable polymer used as a scale inhibitor, dispersant, or corrosion inhibitor in water treatment, agriculture, and industrial cleaning. It is customized for OEM clients to meet specific application requirements.

Q: What are the advantages of OEM polyaspartic acid sodium salt?

A: OEM polyaspartic acid sodium salt offers eco-friendly biodegradability, high thermal stability, and excellent scale inhibition. It is tailored for industrial clients to enhance performance in sectors like cooling systems or detergents.

Q: Which industries use OEM polyaspartic acid sodium salt?

A: Common industries include water treatment, agriculture, oilfield chemicals, and personal care. OEM formulations are optimized for client-specific needs, such as reducing calcium carbonate scaling.

Q: Is OEM polyaspartic acid sodium salt safe according to its MSDS?

A: Yes, the MSDS confirms it is non-toxic and biodegradable, but proper handling (e.g., gloves, eye protection) is advised. OEM providers supply MSDS to ensure compliance with safety regulations.

Q: How can I request an MSDS for OEM polyaspartic acid sodium salt?

A: Contact your OEM supplier directly via email or their website portal. The MSDS will detail safety, storage, and disposal guidelines for the specific formulation provided.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025