News

Sau . 20, 2025 07:10 Back to list

polyaspartic acid synthesis

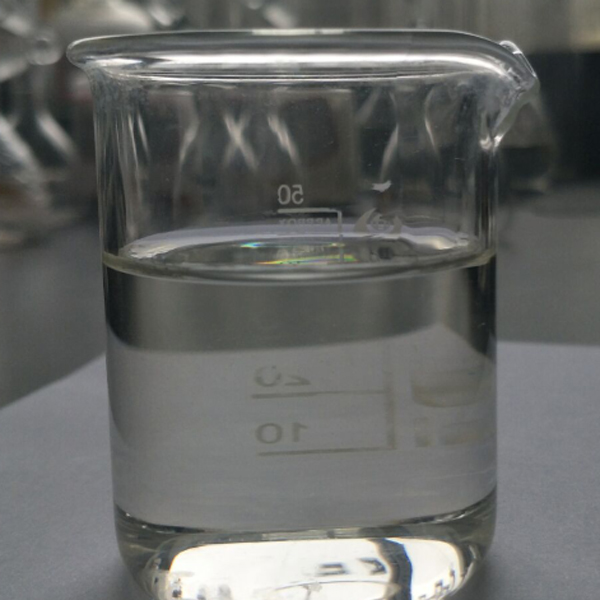

Polyaspartic acid synthesis has seen significant innovations over recent years, presenting exciting opportunities across various industries. This unique polymer is not just a product of advanced chemical engineering but also a promising solution for sustainable product development. Its synthesis involves complex processes that demand both scientific prowess and practical expertise.

The synthesis of polyaspartic acid also offers solutions beyond traditional sectors. In coatings and sealants, its rapid curing times and impressive durability outperform conventional materials. Expertise in polyaspartic formulations has led to the development of coatings that resist environmental wear and tear. Such advancements not only enhance product lifespan but also reduce maintenance costs, making them an attractive option for both industrial and residential use. Expertise in polyaspartic acid synthesis doesn't stop at production; it extends to application and innovation. Continuous research is imperative to expand its potential applications. Scientists and engineers consistently explore ways to modify its chemical structure, aiming to improve performance characteristics like tensile strength, elasticity, and thermal stability. Such modifications enhance suitability across a broader spectrum of uses, from automotive parts to electronic device components. Despite its numerous advantages, challenges in polyaspartic acid synthesis remain. Scalability of production presents hurdles, necessitating investment in advanced manufacturing technologies and infrastructure. Collaboration across chemical industries and academic institutions is crucial to overcome these barriers. Sharing knowledge and advancing research can stimulate innovation, driving the commercial potential of polyaspartic acid to new heights. In conclusion, the synthesis of polyaspartic acid embodies a blend of scientific expertise and practical application. It holds promise for sustainable development across various domains, underscoring the need for ongoing research and industrial collaboration. As technology advances, the possibilities for polyaspartic acid appear limitless, cementing its position as a vital component in the quest for environmentally responsible material solutions.

The synthesis of polyaspartic acid also offers solutions beyond traditional sectors. In coatings and sealants, its rapid curing times and impressive durability outperform conventional materials. Expertise in polyaspartic formulations has led to the development of coatings that resist environmental wear and tear. Such advancements not only enhance product lifespan but also reduce maintenance costs, making them an attractive option for both industrial and residential use. Expertise in polyaspartic acid synthesis doesn't stop at production; it extends to application and innovation. Continuous research is imperative to expand its potential applications. Scientists and engineers consistently explore ways to modify its chemical structure, aiming to improve performance characteristics like tensile strength, elasticity, and thermal stability. Such modifications enhance suitability across a broader spectrum of uses, from automotive parts to electronic device components. Despite its numerous advantages, challenges in polyaspartic acid synthesis remain. Scalability of production presents hurdles, necessitating investment in advanced manufacturing technologies and infrastructure. Collaboration across chemical industries and academic institutions is crucial to overcome these barriers. Sharing knowledge and advancing research can stimulate innovation, driving the commercial potential of polyaspartic acid to new heights. In conclusion, the synthesis of polyaspartic acid embodies a blend of scientific expertise and practical application. It holds promise for sustainable development across various domains, underscoring the need for ongoing research and industrial collaboration. As technology advances, the possibilities for polyaspartic acid appear limitless, cementing its position as a vital component in the quest for environmentally responsible material solutions.

Latest news

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025