News

Nov . 06, 2024 04:52 Back to list

Synthesis and Applications of Polyaspartic Acid for CE Certification Purposes

Synthesis of Polyaspartic Acid A Sustainable Approach towards CE Certification

Polyaspartic acid (PASP) is a biocompatible polymer derived from aspartic acid, an amino acid that is abundant in nature. The interest in PASP has surged over the past few years due to its myriad applications across various industries including textiles, adhesives, coatings, and biomedical fields. One of the primary focuses of research and development in this area has been the optimization of its synthesis to meet stringent environmental and safety regulations, such as CE certification in the European Union.

Understanding Polyaspartic Acid

Polyaspartic acid is a polyamino acid that can be synthesized through the polymerization of aspartic acid, typically using methods that underlie green chemistry principles. Its unique properties such as high biodegradability, excellent adhesion, and non-toxicity make it an ideal candidate for use in environmentally friendly products. PASP has been found in applications such as encapsulation of drugs in medical applications, use as a dispersant in pigments, and as a biodegradable alternative to petrochemical-derived polymers.

The Significance of CE Certification

CE certification marks a product's compliance with European health, safety, and environmental protection legislations. For polymers like PASP, obtaining this certification is crucial as it not only opens the door for access to the European market but also assures consumers that the product is safe and sustainable. CE certification is particularly important for products intended for use in sensitive applications, such as in food packaging or medical devices.

Synthesis Process of Polyaspartic Acid

The synthesis of PASP typically begins with the polymerization of aspartic acid. There are a variety of methods available, but the most common include solution polymerization and solid-state polymerization. Solution polymerization is often conducted under careful control of temperature and pH to ensure homogeneity and reproducibility of the resulting product.

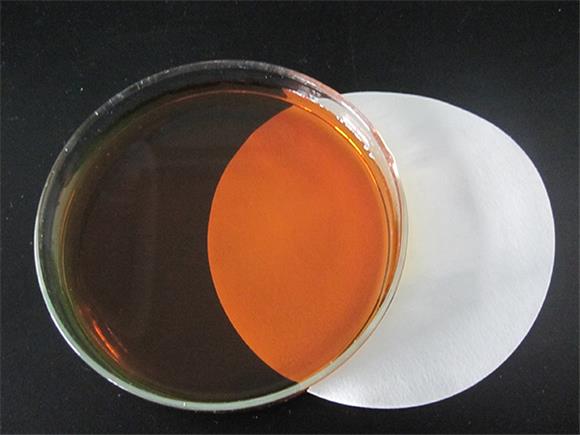

ce certification polyaspartic acid synthesis

- Solution Polymerization In this method, aspartic acid is dissolved in a suitable solvent, and an initiator or catalyst is added to promote polymerization. Various conditions such as temperature, pressure, and reaction time are optimized to achieve the desired molecular weight and chemical properties. - Solid-State Polymerization This process is environmentally friendly as it often eliminates the need for solvents. In solid-state polymerization, aspartic acid is made to undergo polymerization under controlled heat treatment, which allows for higher molecular weights and purer end products.

Green Chemistry Principles in PASP Synthesis

The synthesis of PASP can be aligned with green chemistry principles, which emphasize the reduction of harmful substances and solvents. By optimizing reaction conditions and employing renewable resources, researchers can ensure that the synthesis of PASP is not only efficient but also environmentally sustainable. The use of biocatalysis and enzyme-assisted reactions is also a rising trend, providing pathways that reduce energy consumption and by-product formation.

Applications and Future Perspectives

PASP's unique properties have opened several avenues for practical applications. In biomedical fields, its ability to facilitate drug delivery systems enhances the therapeutic efficacy of medications. In the coatings and adhesives industries, PASP is an excellent binder offering durability while remaining eco-friendly. Companies focused on sustainable practices are increasingly integrating PASP into their product lines, seeking CE certification to enhance their marketability and consumer trust.

Looking to the future, there is significant potential for scaling up the synthesis of PASP and its derivatives. Further research and investment are necessary to explore innovative approaches that can improve methods of synthesis while ensuring compliance with CE certification. Advances in technology, such as the development of more efficient catalysts and reaction conditions, will play a pivotal role in producing high-quality PASP sustainably.

Conclusion

The synthesis of polyaspartic acid is a promising area of research that merges environmental considerations with industrial applications. With the increasing importance of CE certification, the focus on sustainable synthesis methods for PASP not only aligns with regulatory requirements but also meets the rising demand for eco-friendly materials. As innovation continues in this field, polyaspartic acid stands as a testament to the power of science in creating sustainable alternatives in our modern world.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025