News

Aug . 21, 2024 17:55 Back to list

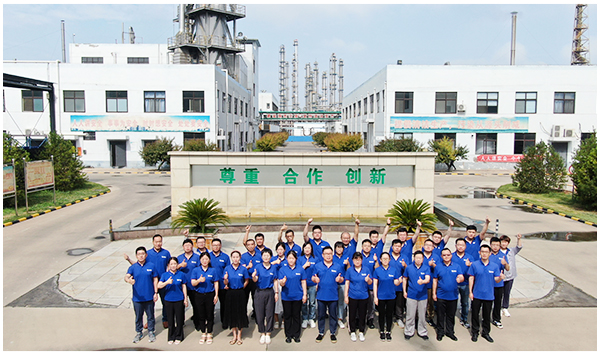

Chelant Chemical Production Facility for Advanced Chemical Solutions and Innovations

The Role of Chelant Chemical Factories in Modern Industry

In the realm of chemical production, chelant chemical factories play a crucial role in addressing various industrial needs, particularly in the fields of agriculture, water treatment, and the manufacturing of consumer products. Chelants, or chelating agents, are molecules that can form multiple bonds with a single metal ion. This unique property enables them to effectively sequester metals, making them invaluable in a variety of applications. This article delves into the significance of chelant chemical factories, their manufacturing processes, and their influence on both industry and the environment.

Understanding Chelants

Chelants are organic compounds that form stable complexes with metal ions, thus facilitating the removal or stabilization of these metals in various settings. For instance, in agriculture, chelants are used to enhance the bioavailability of nutrients such as iron, zinc, and manganese, which are essential for plant growth. In industrial applications, they are employed to control metal ion concentration in wastewater treatment, preventing toxic accumulations that could harm aquatic ecosystems.

Manufacturing Processes

The production of chelating agents involves intricate chemical processes that can vary based on the desired end-product and its application. Common chelating agents include ethylenediaminetetraacetic acid (EDTA), diethylenetriaminepentaacetic acid (DTPA), and citric acid. These compounds are synthesized through a series of chemical reactions, including the reaction of nitrogen-containing compounds with various alkali or acidic reagents.

Chelant chemical factories are equipped with sophisticated equipment and technology to facilitate large-scale production. Modern facilities often employ continuous flow reactors, which allow for the efficient and precise mixing of chemicals. Additionally, quality control measures are paramount in these factories, ensuring that the chelants produced meet industry standards and regulatory requirements.

chelant chemical factory

Applications Across Industries

The applications of chelant chemical products are vast and diverse. In agriculture, chelating agents enable farmers to utilize fertilizers more efficiently, reducing the need for excessive chemical inputs while maximizing crop yield. Furthermore, chelants are critical in the mining industry, where they help extract valuable metals from ores through processes such as hydrometallurgy.

In the water treatment sector, chelants are used to remove heavy metals from industrial effluents, thereby helping industries comply with environmental regulations. This not only protects water quality but also promotes sustainable practices by recycling and reusing water. Moreover, in the realm of consumer products, chelants are often found in personal care items, laundry detergents, and food additives, where they enhance product stability and efficacy.

Environmental Considerations

While chelant chemical factories contribute significantly to industrial productivity and sustainability, they also face scrutiny regarding environmental impact. The production and use of certain chelating agents can lead to concerns about bioaccumulation and the long-term effects on ecosystems. Thus, it is crucial for manufacturers to invest in research and development to create more environmentally friendly alternatives and improve waste management practices.

Conclusion

Overall, chelant chemical factories are vital components of modern industry, providing innovative solutions that enhance productivity and environmental sustainability. Their ability to produce effective chelating agents opens doors in various sectors, from agriculture to water treatment. As industries continue to seek sustainable practices, the role of chelant manufacturers will remain essential, fostering a balance between technological advancement and environmental stewardship. As we look to the future, continuous improvements in production methods and a focus on eco-friendly alternatives will likely shape the next generation of chelating agents and their applications, ensuring that they meet the needs of a changing world.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025