News

Nov . 07, 2024 12:27 Back to list

Leading Manufacturer of Polyglutamic Acid in China for High-Quality Biotech Solutions

Exploring the Landscape of Polyglutamic Acid Manufacturing in China

In recent years, the global demand for biocompatible and biodegradable polymers has surged, driven by advancements in various industries, including cosmetics, pharmaceuticals, and food technology. At the forefront of this biopolymer revolution is polyglutamic acid (PGA), a naturally occurring polymer produced by various microbial species. China has emerged as a leading manufacturer of polyglutamic acid, capitalizing on its rich bioresources and advanced manufacturing capabilities.

What is Polyglutamic Acid?

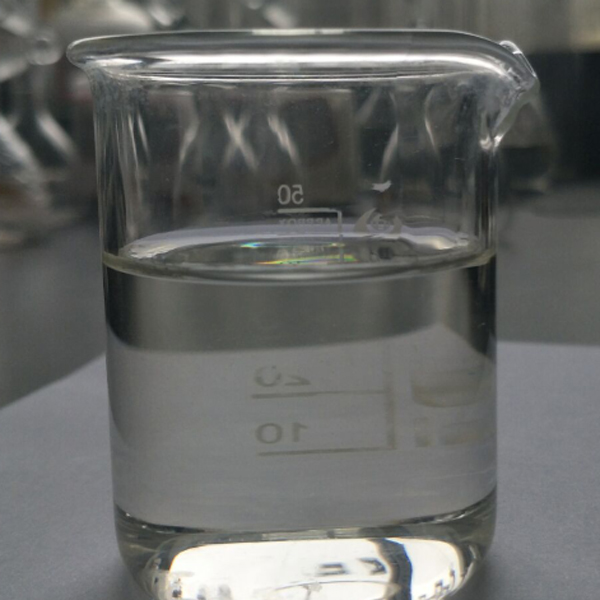

Polyglutamic acid is a biopolymer formed by the polymerization of glutamic acid, an amino acid that plays a crucial role in protein synthesis and cellular functions. PGA exhibits unique properties, such as excellent water solubility, high viscosity, and outstanding moisture-retaining abilities, making it an invaluable ingredient in numerous commercial products. In cosmetics, for example, PGA is revered for its hydrating properties, as it can hold moisture up to 5000 times its weight in water, providing an effective anti-aging solution.

In the food industry, polyglutamic acid is recognized as a natural thickening agent and emulsifier. Its safety and non-toxicity further enhance its appeal, leading to increased adoption in health-conscious markets.

China’s Role in PGA Manufacturing

China has played a pivotal role in the global polyglutamic acid market. The country is not only home to abundant natural resources but also possesses advanced biotechnology and fermentation technology necessary for producing high-quality PGA.

Several Chinese manufacturers utilize fermentation processes involving specific strains of bacteria, such as *Bacillus subtilis*, to produce polyglutamic acid

. These processes yield high quantities of PGA while maintaining cost-efficiency, making China a prime producer for both domestic and international markets.Innovations in Production

china polyglutamic acid manufacturer

Investments in research and development have enabled Chinese manufacturers to innovate and optimize their production techniques. By leveraging cutting-edge biotechnological advancements, companies are enhancing fermentation processes, improving yield, and reducing production times. Furthermore, some manufacturers are experimenting with bioengineering techniques to produce modified versions of PGA for specialized applications, including drug delivery systems and bioactive materials.

Market Dynamics and Opportunities

The growing global awareness of environmental sustainability and the shift towards natural ingredients have catalyzed the demand for polyglutamic acid. In recent years, the cosmetic and skincare sectors have particularly recognized the versatility of PGA, leading to an increase in its incorporation into formulations. As a result, Chinese manufacturers are positioned to expand their market reach, catering to both local and international buyers.

Moreover, the rise of e-commerce platforms has simplified access to these products, allowing smaller companies and startups to enter the market with innovative formulations that include polyglutamic acid.

Challenges Ahead

Despite the promising outlook, the polyglutamic acid manufacturing industry in China faces several challenges. Competition from other biopolymer producers globally is on the rise, with countries like Japan and South Korea also focusing heavily on biotechnology. Additionally, maintaining the quality and consistency of PGA production is crucial, which requires ongoing investment in quality control and sustainable practices.

Conclusion

With its advanced manufacturing capabilities and abundant resources, China is set to remain a critical player in the global polyglutamic acid market. As demand continues to grow across various sectors, Chinese manufacturers must strive to innovate and optimize their production processes to stay ahead. By doing so, they can not only meet the increasing global demand for polyglutamic acid but also contribute to the sustainable development of biopolymer applications worldwide. The future of polyglutamic acid manufacturing in China looks promising, reflecting a blend of tradition, innovation, and sustainability.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025