News

Dec . 15, 2024 14:36 Back to list

Optimizing Production Techniques for Custom Polyglutamic Acid Synthesis and Applications

Custom Polyglutamic Acid Production A Revolutionary Approach in Biotechnology

Polyglutamic acid (PGA) is a natural biopolymer that has garnered significant attention in various fields, including medicine, agriculture, and food science. By leveraging its unique properties, such as biocompatibility, biodegradability, and non-toxicity, researchers and manufacturers have sought to harness the potential of PGA for numerous applications. The custom production of polyglutamic acid has emerged as a cutting-edge solution, enabling tailored properties and functionalities to meet specific industrial needs.

PGA is composed entirely of glutamic acid units linked together through peptide bonds. It can be produced through microbial fermentation, utilizing bacteria such as *Bacillus subtilis* as a primary production organism. The choice of microbial strain, fermentation conditions, and the manipulation of metabolic pathways are all critical factors that affect the yield and properties of PGA. Custom production allows for modifications at each of these stages, resulting in a biopolymer with distinct characteristics tailored to various applications.

One of the most significant advantages of custom polyglutamic acid production is the ability to adjust its molecular weight. The molecular weight of PGA can influence its solubility, viscosity, and biological activity. For instance, low molecular weight PGA has been shown to exhibit enhanced bioactivity in wound healing applications, while high molecular weight PGA may be more suitable for use as a thickening agent in food products. By customizing the production process, manufacturers can generate the right molecular weight for their specific application, enhancing performance and efficacy.

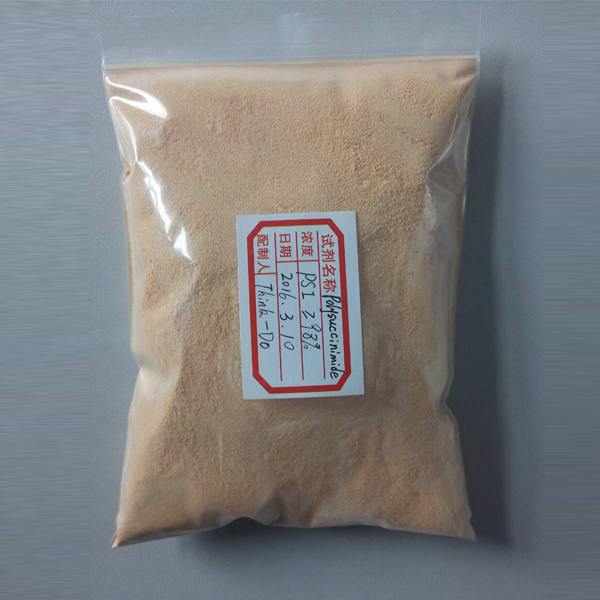

custom polyglutamic acid production

Furthermore, custom production enables the incorporation of functional groups into the PGA molecule. This functionalization can enhance the biopolymer's compatibility with other materials, thereby broadening its range of applications. For example, PGA can be modified to include carboxyl or amine groups, which can facilitate interactions with other polymers or biomolecules. This versatility opens the door for innovative applications, such as drug delivery systems, where PGA can be engineered to release therapeutic agents in a controlled manner.

In the agricultural sector, custom polyglutamic acid production has shown promise as a soil conditioner and bio-stimulant. PGA can improve soil structure, enhance water retention, and promote nutrient availability, ultimately leading to increased crop yield. Custom formulations can be developed to target specific soil types or crop needs, maximizing agricultural productivity and sustainability. Moreover, the use of biodegradable and non-toxic materials like PGA aligns with the growing demand for environmentally friendly agricultural solutions.

The food industry has also benefited from custom PGA production. As a natural thickener, it is increasingly used in a variety of food products, including dressings, sauces, and dairy items. The tailored production of PGA allows manufacturers to create products with specific textures and mouthfeel, enhancing consumer satisfaction. Additionally, the increasing trend towards clean-label products has led food manufacturers to seek natural alternatives to synthetic additives, and PGA fits seamlessly into this paradigm.

In conclusion, the custom production of polyglutamic acid stands at the forefront of biotechnological advancement, offering tailored solutions for a myriad of applications. By manipulating production parameters, including microbial strains, fermentation conditions, and molecular weight, producers can create a biopolymer that meets the diverse needs of industries ranging from agriculture to pharmaceuticals. As research continues to unveil the potential of PGA, it is set to become an essential component in the pursuit of sustainable and innovative solutions across multiple sectors. The future of custom polyglutamic acid production is indeed bright, promising continued advancements that will benefit both industry and the environment alike.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025