News

Aug . 13, 2024 17:48 Back to list

Exploring the Production Process and Innovations at the EDTA-Fena Manufacturing Facility

EDTA-FENA Factory A Hub of Innovation and Sustainability

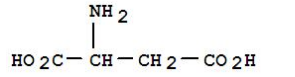

The EDTA-FENA factory represents a cutting-edge approach to the production of essential chemical compounds that play a crucial role in various industries. EDTA (Ethylenediaminetetraacetic acid) and FENA (Ferrous Ethylenediaminetetraacetic Acid) are two important chelating agents widely utilized in agriculture, pharmaceuticals, food industries, and environmental applications. As the demand for these compounds grows in a world increasingly focused on sustainability and efficiency, the EDTA-FENA factory stands at the forefront of innovation.

At its core, the factory is designed to produce high-quality, environmentally friendly EDTA and FENA products. By employing advanced manufacturing technologies and adhering to stringent quality control measures, the facility ensures that its outputs meet the highest standards. This commitment to quality not only enhances the performance of the products but also contributes to the overall sustainability of the production process.

EDTA-FENA Factory A Hub of Innovation and Sustainability

In addition to environmental sustainability, the EDTA-FENA factory places a strong emphasis on research and development. The facility employs a team of skilled scientists and engineers dedicated to exploring new formulations and improving existing processes. This commitment to innovation allows the factory to respond swiftly to market needs and regulatory changes, ensuring that it remains competitive in an ever-evolving industry landscape.

edta-fena factory

Moreover, the importance of EDTA and FENA in various sectors cannot be overstated. In agriculture, these chelating agents enhance nutrient availability in soil, thereby improving crop yields and promoting sustainable farming practices. In the pharmaceutical industry, they are critical in drug formulation and as stabilizers that enhance the efficacy of active ingredients. Additionally, in the food sector, EDTA is used as a preservative, ensuring safety and extending shelf life without compromising quality.

The EDTA-FENA factory is also aware of its responsibilities towards the community and the broader ecosystem. Engaging with local stakeholders, the factory aims to contribute positively to the regional economy by creating job opportunities and fostering partnerships with educational institutions. This collaboration not only prepares the future workforce with the necessary skills but also spurs innovation through cooperative research initiatives.

As industries worldwide continue to prioritize sustainability and efficiency, the EDTA-FENA factory exemplifies how modern manufacturing can align with these goals. By embracing green chemistry, investing in research and development, and engaging with the community, the factory is not just contributing to the market but also setting a standard for others to follow.

In conclusion, the EDTA-FENA factory stands as a testament to the power of innovation and sustainability in chemical manufacturing. By producing essential compounds that support various industries while prioritizing environmental stewardship and community engagement, the factory paves the way for a more sustainable future. As we look ahead, the continued development and success of such facilities will be vital in addressing the global challenges of our time.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025