News

Jul . 26, 2024 12:25 Back to list

High-performance polyaspartic acid products by Bayer for superior applications and enhanced results

The Remarkable Applications of High-Quality Polyaspartic Acid from Bayer

Polyaspartic acid is an emerging front-runner in the world of polymers, displaying a plethora of valuable properties that make it ideal for various applications across industries. Bayer, a global leader in science and innovation, has harnessed the potential of high-quality polyaspartic acid to create products that set new standards in performance and environmental sustainability.

Understanding Polyaspartic Acid

Polyaspartic acid is a biodegradable polymer derived from aspartic acid, an amino acid that is naturally occurring in the human body. This polymer is notable for its excellent adhesion, flexibility, and resistance to chemicals, which makes it an attractive alternative to traditional synthetic polymers. More importantly, polyaspartic acid is recognized for its low toxicity and environmental impact, aligning with global sustainability goals.

Production and Quality Assurance

Bayer has invested significantly in the development of high-quality polyaspartic acid, focusing on the purity and consistency of its products. The company employs cutting-edge technology and rigorous testing protocols to ensure that its polyaspartic acid meets the highest standards. This commitment to quality not only enhances the performance of the end-products but also ensures that they are safe for both consumer use and the environment.

Applications Across Various Industries

1. Coatings Industry One of the most promising applications of high-quality polyaspartic acid is in the coatings sector. Due to its rapid curing properties, it can be used to formulate protective coatings that dry quickly, reducing waiting time and increasing efficiency. These coatings also exhibit high durability and resistance to wear, making them ideal for industrial floors, commercial spaces, and even automotive applications.

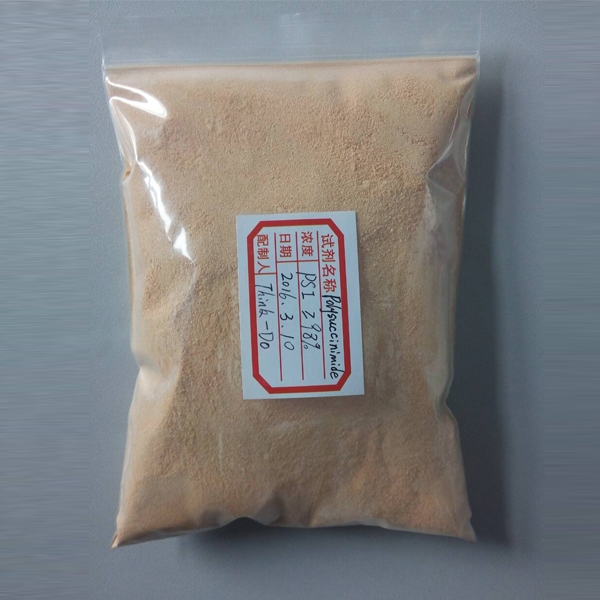

high quality polyaspartic acid bayer

2. Adhesives and Sealants The excellent adhesion characteristics of polyaspartic acid make it an outstanding choice for formulating adhesives and sealants. It provides strong bonding capabilities that can withstand various stresses, making products more reliable and reducing the need for frequent repairs or replacements.

3. Agricultural Applications Bayer’s high-quality polyaspartic acid also finds its place in agriculture, where it can be used as a soil conditioner. It helps in moisture retention and nutrient delivery, fostering healthier plant growth. Furthermore, it aids in the slow release of fertilizers, maximizing their efficiency and reducing environmental runoff.

4. Biomedical Uses With its biocompatibility and low toxicity, polyaspartic acid has attracted attention in the biomedical field. Researchers are exploring its potential for drug delivery systems, wound healing applications, and tissue engineering, where its favorable properties can significantly enhance therapeutic outcomes.

Environmental Impact and Sustainability

Bayer's focus on producing high-quality polyaspartic acid is not only about performance but also about sustainability. As industries shift towards more eco-friendly materials, polyaspartic acid stands out due to its biodegradability and low environmental footprint. By integrating sustainable practices in its production processes, Bayer supports the global move towards a greener economy.

Conclusion

In summary, high-quality polyaspartic acid developed by Bayer exemplifies the potential of innovative materials to address contemporary challenges across various industries. Its diverse applications, combined with environmental sustainability, position polyaspartic acid as a remarkable polymer for the future. By advancing such products, Bayer is not only enhancing the performance of various materials but is also making a significant contribution to a more sustainable world. As research continues to evolve, the possibilities for polyaspartic acid will likely expand, paving the way for new applications and further improvements in quality and efficiency.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025