News

Dec . 05, 2024 04:54 Back to list

High-Quality Versene 220 for Enhanced Performance in Various Applications

Exploring High-Quality Versene 220 An Essential Chemical in Industrial Applications

In the realm of chemistry, the importance of chelating agents cannot be overstated. Among these agents, Versene 220, also known as disodium ethylenediaminetetraacetate (EDTA), stands out for its unique properties and versatility. This article delves into the significance of high-quality Versene 220, highlighting its applications, manufacturing processes, and the key factors that contribute to its quality.

Understanding Versene 220

Versene 220 is a chelating agent widely used across various industries due to its ability to bind metal ions effectively. Its chemical formula—C10H14N2O8Na2—reveals a complex structure that allows it to form stable complexes with metal ions, making it an invaluable component in many applications.

The high-quality variant of Versene 220 is essential to ensure efficacy in its application. Variations in purity and manufacturing processes can significantly impact its performance in different environments. Hence, understanding the composition and manufacturing standards of high-quality Versene 220 is critical for industries that rely on this chemical.

Applications of High-Quality Versene 220

1. Water Treatment One of the primary uses of Versene 220 is in water treatment processes. It effectively removes heavy metals such as lead, mercury, and cadmium, making it an asset for ensuring safe drinking water. High-quality Versene 220 ensures a more effective chelation process, facilitating compliance with environmental safety standards.

2. Food Industry In the food processing sector, Versene 220 acts as a stabilizing agent. It helps in preserving the appearance and integrity of food products by preventing the discoloration caused by metal ions. The food-grade quality of Versene 220 is strictly regulated to ensure consumer safety, making its high quality paramount.

3. Agriculture The agricultural sector benefits from Versene 220 through its role in chelating micronutrients essential for plant growth, such as iron and manganese. Properly formulated Versene 220 enhances nutrient uptake in plants, ensuring higher yield and healthier crops.

4. Cosmetics and Pharmaceuticals In the cosmetics industry, Versene 220 is used for its ability to sequester metal ions that can cause adverse reactions in formulations. Similarly, in pharmaceuticals, it plays a critical role in drug stability and effectiveness.

Manufacturing Process of High-Quality Versene 220

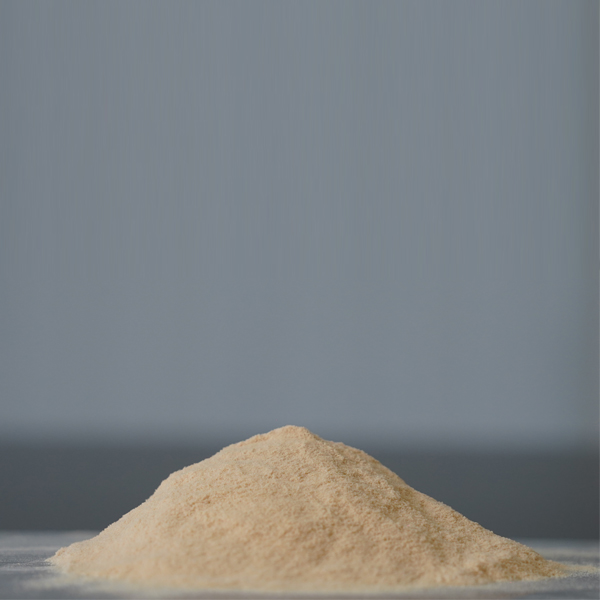

high quality versene 220

The manufacturing of high-quality Versene 220 involves intricate chemical processes to ensure purity and effectiveness. The initial step includes the synthesis of ethylenediamine with acetic acid, followed by neutralization with sodium hydroxide. This process must be meticulously controlled to minimize impurities and ensure that the final product meets the specified quality standards.

Quality control is vital throughout the manufacturing process. Tests for purity, pH levels, and concentration are routinely conducted to verify that the product meets industry standards. Manufacturers often adopt ISO-certified quality management systems to ensure that every batch of Versene 220 is consistent in quality and performance.

Factors Influencing the Quality of Versene 220

1. Raw Material Quality The quality of the raw materials used in the production of Versene 220 directly affects the final product. High-purity reagents must be sourced to prevent contamination.

2. Production Environment A controlled manufacturing environment minimizes exposure to factors that could compromise quality. This includes maintaining strict temperature and humidity levels.

3. Testing and Compliance Regular testing for heavy metals and other impurities is essential to ensure that the Versene 220 remains compliant with safety regulations.

4. Expertise of Manufacturer The skill and experience of the manufacturing team play a crucial role in producing high-quality Versene 220. Adept chemists are required to navigate the complex synthesis and purification processes effectively.

Conclusion

In conclusion, high-quality Versene 220 is a vital ingredient in various industrial applications, from water treatment and food production to agriculture and cosmetics. Its effectiveness as a chelating agent is influenced by the quality of its production and the raw materials used. As industries continue to rely on high-quality chemicals to meet regulatory standards and consumer expectations, the demand for superior Versene 220 will likely grow.

Therefore, ensuring its production adheres to high standards not only benefits manufacturers and industries but also contributes to a sustainable and safe environment for all.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025