News

Dec . 06, 2024 05:03 Back to list

Leading Producers of Polyglutamic Acid for Various Applications in the Market Today

Understanding Polyglutamic Acid The Role of Manufacturers in the Beauty and Health Industry

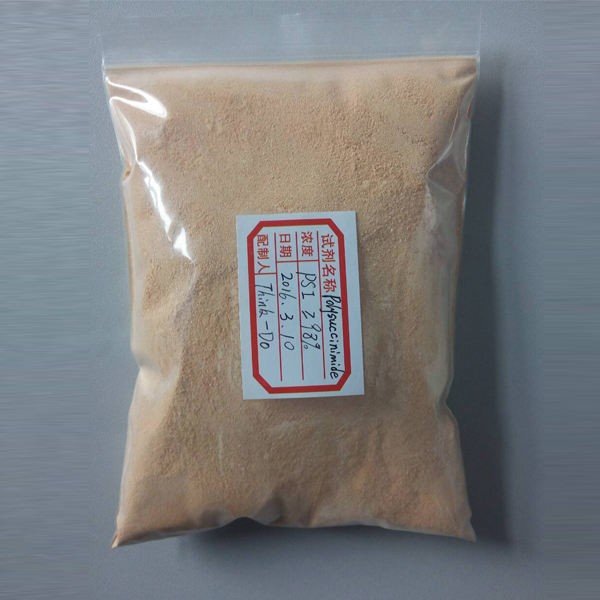

Polyglutamic Acid (PGA) has emerged as a significant ingredient in the skincare and health industry due to its remarkable properties and potential benefits. Manufacturers of polyglutamic acid play a crucial role in making this unique compound widely available to consumers, fostering an influx of products that promise enhanced hydration, skin elasticity, and overall health.

What is Polyglutamic Acid?

Polyglutamic acid is a naturally occurring polymer formed by the polymerization of glutamic acid, an amino acid found abundantly in certain fermented foods and soy products. Unlike its more famous counterpart, hyaluronic acid, which is renowned for its water-retaining capabilities, polyglutamic acid has the ability to hold up to 5,000 times its weight in water. This unparalleled moisture retention makes it an exemplary ingredient in skincare formulations designed to combat dryness and aging.

Not only is polyglutamic acid a humectant, drawing moisture into the skin, but it also creates a protective barrier that prevents water loss. This dual action can significantly improve skin texture and hydration levels, making products containing PGA particularly popular in the realm of moisturizers, serums, and masks.

The Role of Manufacturers

The success of polyglutamic acid in the consumer market is largely attributed to the dedication and innovation of its manufacturers

. These entities are responsible for sourcing high-quality raw materials, ensuring the production of pure and effective PGA that meets regulatory standards and consumer demands.inkey polyglutamic acid manufacturer

1. Sourcing and Production Responsible manufacturers focus on obtaining glutamic acid from sustainable and reliable sources. This ensures not only the quality of the final product but also its environmental impact. Through advanced fermentation processes, manufacturers can produce polyglutamic acid in a way that is both efficient and eco-friendly.

2. Quality Control Stringent quality control measures are essential for manufacturers to maintain the integrity and efficacy of their products. Regular testing during manufacturing processes ensures that the polyglutamic acid produced is free from contaminants and maintains its functional properties. This commitment to quality builds trust with consumers and enhances brand reputation.

3. Innovation and Research Continuous research and development are pivotal in the world of manufacturing. Leading companies in the polyglutamic acid space invest in R&D to explore new applications and formulations. This innovation leads to the creation of novel skincare products that incorporate PGA, such as anti-aging creams and hydrating gels, thus meeting the diverse needs of consumers.

4. Education and Marketing Beyond manufacturing, educating consumers about the benefits and uses of polyglutamic acid is vital. Manufacturers often engage in marketing campaigns that highlight the science behind PGA and its advantages over traditional moisturizers. By disseminating knowledge, they empower consumers to make informed choices about their skincare routines.

Conclusion

Polyglutamic acid represents a significant advancement in skincare technology, promising increased hydration and skin health. The role of manufacturers is critical in this landscape, as they not only produce high-quality PGA but also facilitate its access to consumers through innovative products and educational initiatives. As demand for effective, science-backed skincare solutions continues to grow, manufacturers of polyglutamic acid will undoubtedly remain at the forefront of the beauty and health industry, shaping the future of skincare with their expertise and commitment to quality.

Understanding the intricate processes behind the production and distribution of polyglutamic acid can enhance appreciation for this remarkable ingredient and its potential benefits in everyday skincare routines.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025