News

Jul . 28, 2024 18:18 Back to list

Innovative Solutions for Liquid Micronutrient Fertilizer Production and Application Services for Farmers

The Role of Micronutrient Fertilizer Liquid Manufacturers in Sustainable Agriculture

In recent years, the agricultural sector has faced numerous challenges, including soil depletion, climate change, and the growing demand for food production. To address these issues, farmers and agronomists are increasingly turning to micronutrient fertilizers in liquid form. These fertilizers play a crucial role in enhancing crop yield and quality, and their manufacturing is essential to sustainable agriculture practices worldwide.

Understanding Micronutrients

Micronutrients are essential elements that crops require in small quantities for their growth and development. These include iron, manganese, zinc, copper, molybdenum, boron, and chlorine. Although they are needed in small amounts, their deficiency can lead to significant yield losses and reduced crop quality. For instance, a lack of zinc can cause stunted growth and yellowing leaves, while insufficient iron can lead to chlorosis, affecting the plants' overall health.

The Advantages of Liquid Micronutrient Fertilizers

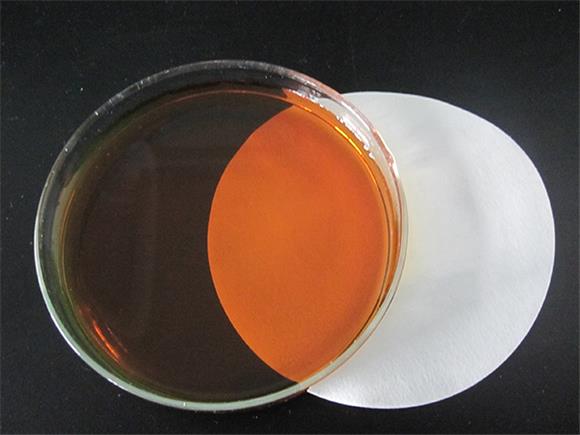

Liquid micronutrient fertilizers offer several advantages over their solid counterparts. Firstly, they are easily absorbed by plants, allowing for quicker and more efficient nutrient uptake. This is particularly important during crucial growth stages when plants are most vulnerable to nutrient deficiencies. Secondly, liquid fertilizers can be applied through fertigation systems, reducing labor costs and enhancing convenience for farmers. Additionally, they can be mixed with other fertilizers or pesticides, further streamlining the application process.

The Role of Manufacturers

micronutrient fertilizer liquid manufacturer

Micronutrient fertilizer liquid manufacturers play a pivotal role in the agricultural supply chain. Their expertise in formulating and producing high-quality fertilizers ensures that farmers have access to the nutrients their crops need. These manufacturers invest in research and development to create tailored solutions that address specific soil and crop requirements based on regional conditions.

Moreover, environmental sustainability is a growing concern, and leading manufacturers are now focusing on producing eco-friendly formulations that minimize the environmental impact of fertilization. This includes developing biodegradable products and employing sustainable practices in the manufacturing process.

Quality Control and Compliance

Quality control is paramount in the production of micronutrient fertilizers. Manufacturers must adhere to strict regulations and standards to ensure their products are safe and effective. Regular testing of raw materials and finished products helps maintain high-quality standards and ensures that the micronutrient content meets the specified guidelines. Additionally, compliance with environmental regulations is necessary to minimize the ecological footprint of fertilizer production.

Conclusion

The role of micronutrient fertilizer liquid manufacturers is indispensable in contemporary agriculture. As global food demand continues to rise amidst environmental challenges, these manufacturers are essential in providing farmers with the tools they need to enhance crop health and productivity. By supplying high-quality, easily absorbable fertilizers, they not only contribute to food security but also promote sustainable farming practices. As the agricultural landscape evolves, the collaboration between farmers and micronutrient fertilizer manufacturers will be vital in addressing the complex challenges of modern agriculture.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025