News

Oct . 06, 2024 22:55 Back to list

l and d aspartic acid manufacturer

The Role of L- and D-Aspartic Acid Manufacturers in the Global Market

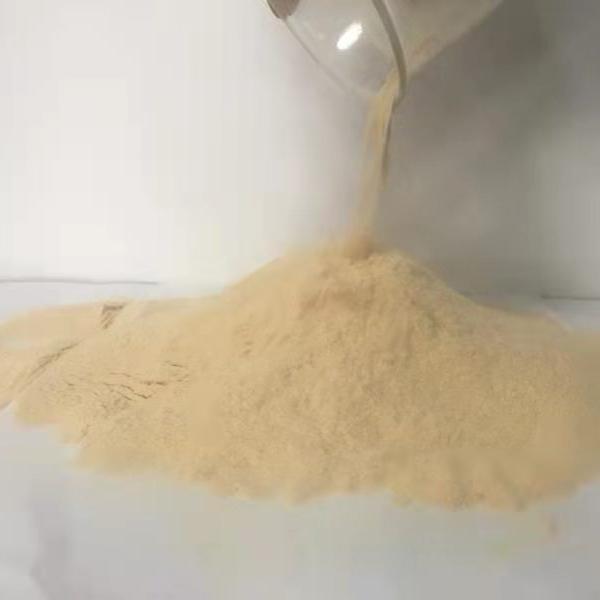

Aspartic acid, an alpha-amino acid used in the biosynthesis of proteins, is prevalent in various applications ranging from food production to pharmaceuticals. It exists in two principal forms L-aspartic acid and D-aspartic acid. Both forms serve important roles, yet they exhibit distinct characteristics and functions, leading to diverse applications in different industries. The manufacturing of these two forms of aspartic acid is pivotal in meeting the growing global demand.

Understanding L- and D-Aspartic Acid

L-aspartic acid is the naturally occurring form found in proteins. It plays a crucial role in the biosynthesis of other amino acids and serves as a neurotransmitter in the central nervous system. It has been extensively studied for its potential benefits in boosting athletic performance and improving energy levels, making it popular in dietary supplements. On the other hand, D-aspartic acid, though less common, is known for its role in hormonal regulation, particularly in the production of testosterone. It is often marketed to bodybuilders and athletes seeking enhanced physical performance and recovery.

Market Demand and Applications

The demand for L- and D-aspartic acid has surged in recent years due to their wide-ranging applications. In the food industry, L-aspartic acid is used as a flavor enhancer and is integral to the production of artificial sweeteners like aspartame, which is widely used in low-calorie and sugar-free products. The pharmaceutical industry utilizes aspartic acid in the formulation of various drugs, including those for neurological disorders.

D-aspartic acid, while less utilized in food, has gained traction in the sports nutrition sector. Athletic supplements containing D-aspartic acid claim to enhance testosterone production, leading to increased muscle mass and improved athletic performance. This particular application has attracted significant attention, promoting research and development efforts focused on its benefits and efficacy.

l and d aspartic acid manufacturer

Manufacturing Processes

The production of L- and D-aspartic acid typically involves both fermentation and chemical synthesis. Fermentation processes utilize microbial strains capable of converting simple carbohydrates into amino acids. This method is generally favored for L-aspartic acid due to its natural occurrence and ease of uptake by the body. Chemical synthesis, on the other hand, is often employed for producing D-aspartic acid, as it is less prevalent in nature.

Quality assurance during the manufacturing process is crucial. Manufacturers must adhere to strict regulatory guidelines to ensure that the final products meet safety and quality standards. This includes routine testing for contaminants and verifying the purity of the amino acids produced. As the global market becomes increasingly competitive, manufacturers that prioritize high-quality production methods will stand out.

Challenges in the Industry

Despite the promising market for L- and D-aspartic acid, several challenges persist. The fluctuation in raw material prices can significantly impact production costs. Moreover, the rising competition from alternative amino acid sources and synthetic substitutes poses a threat to traditional manufacturers. Keeping up with the latest scientific research and consumer trends is essential for companies to maintain their market position and innovate effectively.

Conclusion

The role of L- and D-aspartic acid manufacturers is crucial in supporting various industries, particularly food and pharmaceuticals. With the increasing acceptance and demand for these amino acids, manufacturers must navigate challenges while embracing opportunities for growth. Innovation in production methods and a focus on quality will be key factors in ensuring success in this ever-evolving market. As consumers become more health-conscious and performance-driven, the relevance of L- and D-aspartic acid will likely continue to rise in the coming years, making it an exciting field for manufacturers and consumers alike.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025