News

Nov . 29, 2024 15:43 Back to list

Mercury Chelant Production Facility for Advanced Environmental Solutions and Applications

The Role of Mercury Chelant Factories in Modern Chemistry

In recent years, the environmental impact of heavy metals, particularly mercury, has drawn significant attention. Mercury is a toxic element that has detrimental effects on both human health and the environment. Its presence in ecosystems can lead to bioaccumulation in food chains, ultimately affecting wildlife and human populations. To combat these challenges, the chemical industry has developed advanced techniques and products, one of which is mercury chelants.

Understanding Mercury Chelants

Mercury chelants are chemical compounds that can bond with mercury ions to form stable complexes, effectively reducing mercury's bioavailability and toxicity. Chelation involves the creation of multiple bonds between a chelator and a metal ion, such as mercury. This process allows for the safe removal of mercury from contaminated environments, making chelants indispensable in various industrial applications, including wastewater treatment, soil remediation, and pharmaceutical development.

The Importance of Mercury Chelant Factories

Mercury chelant factories play a crucial role in the production of these important chemical compounds. These specialized facilities employ sophisticated methods to manufacture chelating agents that are not only effective but also environmentally friendly. The production process involves sourcing raw materials, which are then chemically modified and purified to create high-quality chelating agents tailored to specific applications.

In recent years, the demand for mercury chelants has surged due to increasing regulations on mercury emissions and growing awareness of environmental pollution. Factories are responding by optimizing their production processes to enhance efficiency while minimizing waste. Many mercury chelant factories are implementing green chemistry principles, which emphasize the design of chemical products and processes that reduce or eliminate hazardous substances.

Applications of Mercury Chelants

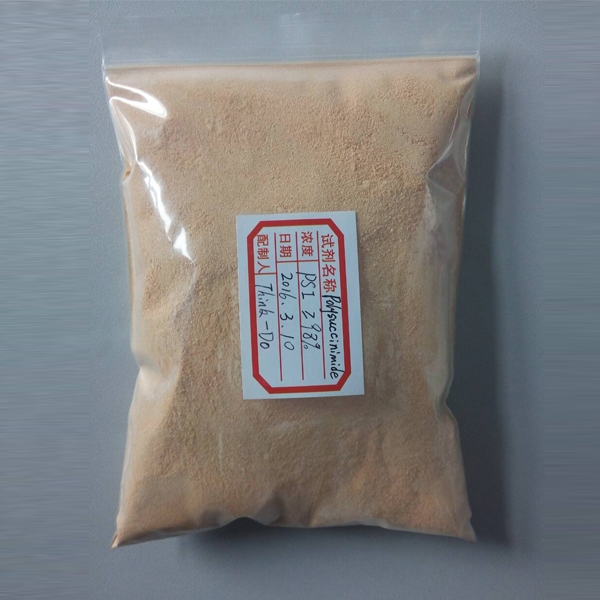

mercury chelant factory

The applications of mercury chelants are diverse and impactful. One of the most significant industries benefiting from these chelants is environmental remediation. Contaminated sites, such as old mining areas or industrial locations, can harbor high levels of mercury. Mercury chelants facilitate the extraction of mercury from sediments and soils, allowing for safer restoration of these environments.

In addition to environmental applications, mercury chelants are also used in medicine. They serve as treatment options for mercury poisoning, helping to bind and excrete mercury from the human body. The pharmaceutical industry leverages these compounds to develop effective antidotes, showcasing the critical intersection of chemistry and public health.

Moreover, industries such as agriculture utilize mercury chelants to enhance soil fertility. These compounds can mitigate the effects of heavy metal contamination in soils, promoting healthier plant growth. This application not only benefits agricultural productivity but also contributes to sustainable farming practices by restoring contaminated land.

Challenges and Future Directions

Despite the advancements in mercury chelant production, challenges remain. Researchers are continually seeking more effective and selective chelants that can target mercury without affecting other essential metal ions in the environment. Additionally, regulatory frameworks are becoming stricter, necessitating factories to adapt their processes to comply with emerging environmental standards.

The future of mercury chelant factories lies in innovation. Investments in research and development will be vital to enhancing the efficiency and effectiveness of chelating agents. Collaborations between industries, academic institutions, and government agencies will foster the development of new chelating technologies. Furthermore, sustainability must remain a priority, as the chemical industry transitions toward more eco-friendly practices.

Conclusion

Mercury chelant factories are vital players in the quest for a cleaner and healthier environment. By producing effective chelating agents, these factories contribute to mitigating the risks associated with mercury contamination and play a significant role in various industries, including environmental remediation, healthcare, and agriculture. As the world continues to grapple with the challenges posed by heavy metal pollution, the importance of mercury chelants and the factories that produce them will only grow, highlighting a promising frontier in modern chemistry. Through ongoing innovation and a commitment to sustainability, these factories can help pave the way for a brighter, mercury-free future.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025