News

Nov . 08, 2024 20:59 Back to list

oem applications of polyaspartic acid

Applications of Polyaspartic Acid in OEM Industries

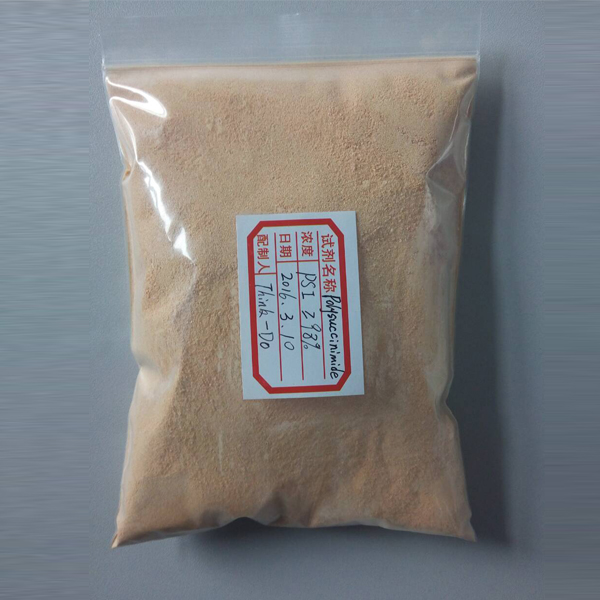

Polyaspartic acid (PAA) is a polyamino acid derived from aspartic acid, a naturally occurring amino acid. Due to its unique chemical properties, polyaspartic acid has garnered significant attention in various industries, especially in Original Equipment Manufacturer (OEM) applications. Its versatility, biodegradability, and eco-friendliness make it an excellent candidate for a range of uses, from coatings and adhesives to biomedicine. This article will explore the diverse applications of polyaspartic acid in OEM contexts.

1. Coatings and Sealants

One of the most prominent applications of polyaspartic acid is in the formulation of coatings and sealants. Its fast-curing properties allow for the rapid application of protective layers on surfaces such as metals, wood, and concrete. Polyaspartic coatings are known for their exceptional durability, UV stability, and resistance to chemicals, making them ideal for industrial environments and outdoor applications. They are widely used in automotive finishes, industrial equipment, and protective coatings for buildings. The rapid curing time also minimizes downtime, which is critical for OEMs that need to keep production lines moving.

2. Adhesives and Sealants

In addition to coatings, polyaspartic acid is also utilized in producing high-performance adhesives and sealants. Its strong bonding capabilities and flexibility make it suitable for various substrates, including plastics, metals, and wood. OEMs benefit from its ability to provide robust and lasting adhesion, particularly in applications requiring resistance to temperature fluctuations and environmental stress. Industries such as automotive, aerospace, and construction leverage polyaspartic adhesives to enhance product durability and performance.

3. Biomedical Applications

Polyaspartic acid has shown promise in the biomedical field, particularly due to its biocompatibility and biodegradability. It can be used in drug delivery systems, tissue engineering scaffolds, and various biomedical devices. The nature of polyaspartic acid allows for the modification of its chemical structure, enabling the development of materials that can release therapeutic agents at controlled rates. OEMs involved in medical device manufacturing can explore polyaspartic acid as a component in creating more efficient and safer products.

oem applications of polyaspartic acid

In the agricultural sector, polyaspartic acid is being utilized as a biodegradable polymer for slow-release fertilizers and soil conditioners. By controlling the release rate of nutrients, polyaspartic acid enhances plant growth and reduces the environmental impact of fertilizer runoff. OEMs in agricultural equipment can also explore incorporating PAA into their products to improve soil health and crop yields, aligning with sustainable farming practices.

5. Water Treatment

Polyaspartic acid is gaining traction in water treatment processes. Its chelating properties allow it to bind with heavy metals and other contaminants, facilitating their removal from water sources. This application is particularly relevant for OEMs designing water filtration systems and treatment facilities, as the use of polyaspartic acid can enhance the efficacy of their products while contributing to environmental sustainability.

6. Green Chemistry

As industries increasingly focus on sustainability, polyaspartic acid stands out due to its biodegradable nature and low environmental impact. Its synthesis from renewable resources aligns with the principles of green chemistry, making it an attractive option for OEMs aiming to reduce their ecological footprint. By incorporating polyaspartic acid into their product lines, manufacturers can meet the growing consumer demand for eco-friendly solutions.

Conclusion

The applications of polyaspartic acid in OEM industries demonstrate its versatility and potential to drive innovation in various sectors. From coatings and adhesives to biomedical and agricultural solutions, polyaspartic acid offers unique properties that address contemporary challenges. As OEMs continue to seek sustainable and high-performance materials, polyaspartic acid is likely to play an increasingly significant role in shaping the future of manufacturing and product development. Its eco-friendly profile, combined with exceptional functional characteristics, positions polyaspartic acid as a valuable resource in the pursuit of advancing technology while adhering to sustainability goals.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025