News

Nov . 10, 2024 08:31 Back to list

Customizable Metal Chelating Agents for OEM Applications in Various Industries

The Importance of OEM Metal Chelating Agents in Modern Industries

In recent years, the need for effective metal chelating agents has grown exponentially across various industries. These compounds, which bind and sequester metal ions, play a crucial role in a wide range of applications, from water treatment to agriculture and industrial processes. Among the many types of chelating agents available, OEM (Original Equipment Manufacturer) metal chelating agents have emerged as particularly notable for their quality and specificity.

What are Metal Chelating Agents?

Metal chelating agents are compounds that can form stable complexes with metal ions, effectively locking them up to prevent them from reacting with other substances. This process helps in mitigating various issues associated with free metal ions, such as toxicity, precipitate formation, and detrimental reactions in biological and chemical systems. The ability to selectively bind specific metals makes chelating agents invaluable in sectors such as pharmaceuticals, food processing, and environmental remediation.

Why OEM Metal Chelating Agents?

The term OEM refers to companies that produce products that are later sold under the brand names of other companies. In the context of metal chelating agents, OEM products are often tailored to meet the precise needs of specific industries or applications, ensuring that the agents provide optimal performance. This customization is vital, as different applications necessitate different properties in a chelating agent, including pH stability, selectivity for specific metals, and compatibility with other chemicals.

1. Tailored Solutions OEM manufacturers often work closely with their clients to develop chelating agents that are specifically formulated for the intended application. This level of customization can lead to enhanced efficacy, reduced environmental impact, and lower operational costs.

2. Quality Control OEM manufacturers typically adhere to rigorous quality control standards, ensuring that their chelating agents meet industry regulations and are safe for use. This high-level quality assurance is crucial in sensitive sectors, like healthcare and food production, where contamination or inconsistent product quality can have serious consequences.

3. Cost-Effectiveness By utilizing OEM services, companies can benefit from economies of scale. OEM suppliers can produce metal chelating agents at lower costs due to their specialized processes and large-scale production capabilities, translating into savings for the client.

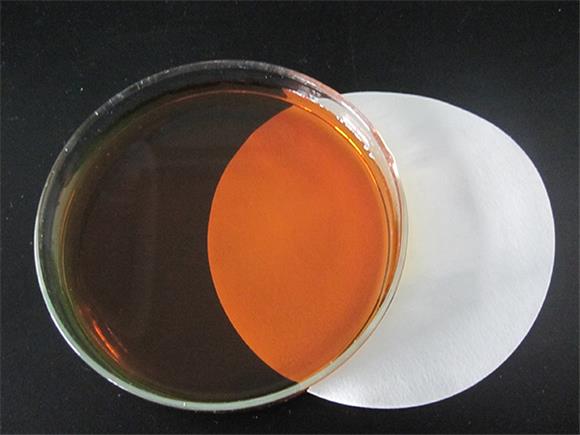

oem metal chelating agent

4. Innovation and Development Many OEM manufacturers are at the forefront of research and development in the field of chelation chemistry. They invest in the development of new formulations that exhibit improved performance or novel functionalities, presenting their clients with cutting-edge solutions that can enhance operational efficiencies and product effectiveness.

Applications of Metal Chelating Agents

1. Water Treatment Metal chelating agents are integral in water treatment processes, where they help to remove heavy metals from wastewater, making it safe for disposal or re-use. Their application is essential in industries where metal contamination is prevalent, like mining and electroplating.

2. Agriculture In agriculture, metal chelating agents are used to enhance the availability of micronutrients such as iron, manganese, and zinc to plants. By forming chelates with these metals, they prevent them from precipitating in the soil and make them more accessible to crops, which promotes healthier plant growth.

3. Pharmaceuticals and Healthcare Metal chelating agents play a significant role in medical treatments, such as chelation therapy for heavy metal poisoning. They are also used as stabilizers in drug formulations, ensuring that active compounds remain effective and safe during storage.

4. Industrial Cleaning In industrial processes, chelating agents help improve the efficacy of cleaning agents by binding to metal ions that can interfere with cleaning processes, thus enhancing the cleaning power and efficiency of detergents and surfactants.

Conclusion

The role of OEM metal chelating agents in modern industries cannot be overstated. Their ability to effectively bind metal ions provides solutions to some of the most pressing challenges faced by numerous sectors. As industries continue to evolve and the demand for high-performance, customized products grows, OEM metal chelating agents will remain at the forefront of innovation and application, paving the way for a cleaner, safer, and more efficient future. In this way, the importance of metal chelating agents will only continue to expand, reinforcing their role as essential components in modern industrial chemistry.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025