News

Oct . 04, 2024 23:39 Back to list

oem polyaspartic acid cost

Cost Analysis of OEM Polyaspartic Acid

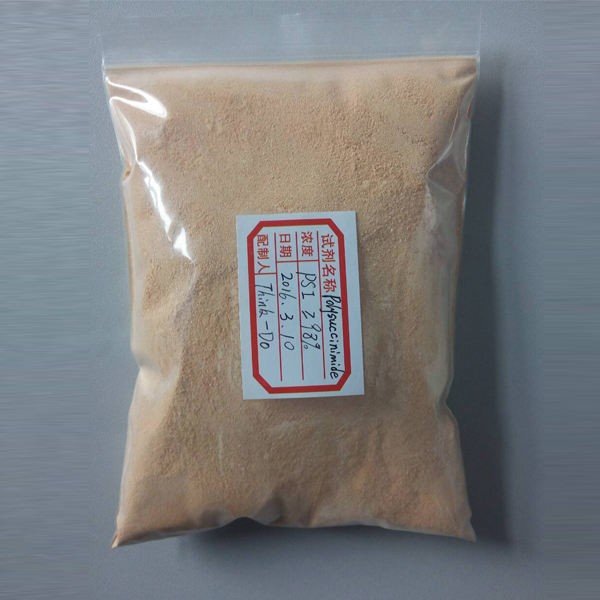

Polyaspartic acid, a relatively recent entrant in the world of polymers, has generated considerable attention due to its versatile applications in various industries, including coatings, adhesives, and construction. As a biodegradable polyamino acid, it boasts numerous beneficial properties such as enhanced durability, UV resistance, and flexibility, making it an attractive option for manufacturers. However, one critical aspect that influences its adoption is the cost associated with its production and procurement, particularly in an Original Equipment Manufacturer (OEM) context. This article delves into the factors that impact the cost of OEM polyaspartic acid and its implications for businesses.

Understanding OEM Polyaspartic Acid Costs

The cost of OEM polyaspartic acid can be influenced by several factors, including raw material expenses, production methods, scale of production, and logistical considerations. Raw materials typically represent a significant portion of the overall cost. Polyaspartic acid is derived from aspartic acid, which is primarily produced from petrochemical sources. Fluctuations in the price of these raw materials can directly impact the final cost of the polymer.

Additionally, the production method for polyaspartic acid can vary widely. Most manufacturers opt for either batch or continuous production processes, each with its own set of cost implications. Batch production may offer flexibility for smaller production runs, whereas continuous processes often benefit from economies of scale, resulting in lower costs per unit when producing large quantities. The choice of production method depends on the desired volume, customization needs, and available resources.

Economies of Scale and Market Demand

The scale of production is intrinsically linked to the pricing structure of OEM polyaspartic acid. Larger manufacturers who can produce polyaspartic acid in bulk often achieve significant cost savings compared to smaller players. This discrepancy can create a competitive landscape where larger companies can offer lower prices, potentially squeezing smaller manufacturers out of the market. Consequently, understanding market demand and adjusting production strategies accordingly is essential for maintaining competitive pricing.

oem polyaspartic acid cost

Moreover, the recent trend toward sustainable and eco-friendly products has driven an increase in demand for polyaspartic acid. As industries and consumers alike prioritize environmental considerations, the demand for biodegradable and less toxic alternatives has surged. This heightened interest may lead to price volatility in the raw materials required for production, as suppliers respond to changing market dynamics.

Logistics and Supply Chain Considerations

Logistics and supply chain management also play a crucial role in determining the cost of OEM polyaspartic acid. Shipping, storage, and handling costs can significantly impact the overall pricing. As manufacturers source raw materials from different regions, fluctuations in shipping rates or delays in the supply chain can cause significant revenue loss. Therefore, maintaining a well-optimized supply chain is essential for keeping costs in check.

Quality and Product Differentiation

The cost of OEM polyaspartic acid is also influenced by the quality and specificity of the product. Manufacturers offering high-purity polyaspartic acid or tailored formulations may charge a premium price due to the added value. On the other hand, those producing standard polyaspartic acid may face pricing pressures as competition increases. Businesses looking to differentiate their products must carefully navigate these pricing strategies while ensuring they do not compromise on quality.

Conclusion

In conclusion, the cost of OEM polyaspartic acid is a multi-faceted issue influenced by raw material prices, production methods, economies of scale, market demand, and logistics. As demand for sustainable materials continues to rise, the landscape for polyaspartic acid will likely experience both challenges and opportunities. For manufacturers, understanding these dynamics is vital to optimizing their production processes and pricing strategies, enabling them to thrive in an increasingly competitive marketplace. As the industry evolves, staying abreast of cost factors will be crucial for success in the rapidly developing world of polyaspartic acid applications.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025