News

Dec . 05, 2024 17:41 Back to list

Exploring the Benefits of OEM Protein Retarders for Enhanced Product Stability

Understanding OEM Protein Retarders Enhancing Food Preservation and Quality

In the ever-evolving landscape of food science, the quest for improved preservation methods has led to the development of various additives that extend shelf life while maintaining food quality. One such innovation is the OEM protein retarder. This specialized additive plays a crucial role in the food industry by inhibiting microbial growth and enhancing the stability of protein-containing products, making it an essential component in modern food preservation techniques.

The Need for Protein Retarders

Proteins are fundamental components of many food products, contributing to texture, flavor, and nutritional value. However, they are also highly susceptible to spoilage caused by microbial activity. This spoilage not only affects the safety and quality of food but can also lead to significant economic losses. To combat this issue, manufacturers have turned to protein retarders, which are designed to delay spoilage and maintain the integrity of protein-rich foods.

What is an OEM Protein Retarder?

OEM, or Original Equipment Manufacturer, refers to products that are manufactured by one company and packaged or marketed by another. In the context of protein retarders, OEM protein retarders are specialized formulations sourced from manufacturers who focus on creating effective and safe food additives. These retarders typically contain a combination of natural and synthetic ingredients that work together to inhibit microbial growth, enhance stability, and extend shelf life.

Mechanism of Action

The primary mechanism by which OEM protein retarders function is through the inhibition of microbial growth. They achieve this by creating an environment that is unfavorable for microbial proliferation, often by adjusting pH levels or through the release of specific antimicrobial compounds. Some protein retarders may also contain enzymes that break down proteins into smaller peptides, which can further discourage the growth of spoilage organisms.

Benefits of Using Protein Retarders

1. Extended Shelf Life One of the most significant advantages of using OEM protein retarders is the extension of shelf life for protein-rich foods. This is especially vital in the meat, dairy, and prepared meal sectors, where spoilage can occur rapidly.

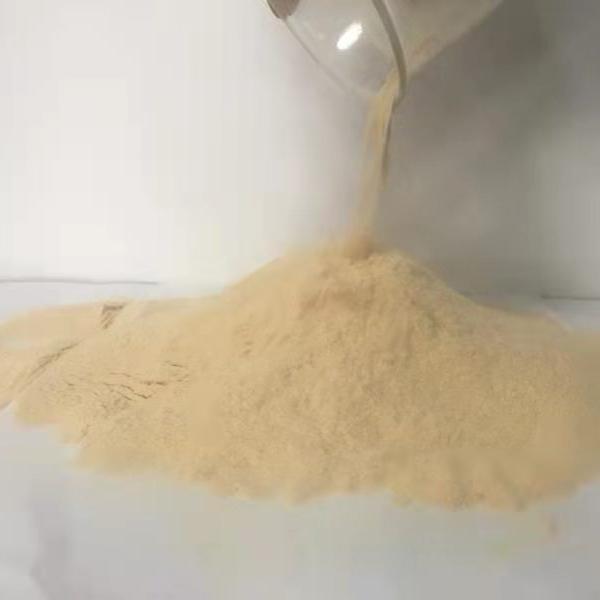

oem protein retarder

2. Maintained Quality By preventing microbial growth, these retarders help maintain the flavor, texture, and overall quality of food products. This ensures that consumers receive fresh and appealing products even after an extended period.

3. Safety With food safety regulations becoming increasingly stringent, the use of protein retarders can help manufacturers meet compliance standards by reducing the risk of foodborne illnesses caused by spoilage organisms.

4. Cost Savings By extending shelf life and reducing spoilage, manufacturers can save on costs related to waste and product recalls. This efficiency translates to improved profitability for food businesses.

Applications in the Food Industry

OEM protein retarders are versatile and can be used across various segments of the food industry. They are commonly incorporated into

- Meat Products Sausages, deli meats, and marinated proteins benefit significantly from the inclusion of protein retarders to delay off-flavors and maintain safety. - Dairy Products In cheese and yogurt production, these additives help manage microbial populations, enhancing product stability.

- Ready-to-Eat Meals Prepared meals often contain multiple protein sources, making protein retarders essential to ensure that these complex products remain safe and enjoyable for consumers.

Conclusion

In conclusion, OEM protein retarders are a vital innovation in the food industry, addressing the challenges associated with protein spoilage. By enhancing shelf life, maintaining quality, and ensuring safety, these specialized additives have become indispensable tools for food manufacturers. As consumer demand for safe, high-quality food products continues to rise, the role of OEM protein retarders will only become more prominent, driving advancements in food preservation techniques and contributing to the overall growth of the food sector.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025