News

Oct . 03, 2024 08:21 Back to list

Polyaspartic Acid Coatings Manufacturer for Durable and High-Performance Protective Solutions

The Rising Prominence of Polyaspartic Acid Coatings in the Industrial Coating Sector

In recent years, the evolution of coating technologies has led to innovative solutions designed to meet the diverse needs of various industries. Among these, polyaspartic acid coatings are gaining remarkable attention for their unique properties and advantages. As a leading development in the realm of protective coatings, polyaspartic acid offers remarkable durability, flexibility, and resistance to environmental factors, making it an optimal choice for many applications. This article will delve into what polyaspartic acid coatings are, their benefits, and their growing relevance in various sectors, including construction, automotive, and manufacturing.

What Are Polyaspartic Acid Coatings?

Polyaspartic acid coatings are polymeric materials derived from aliphatic isocyanates and polyaspartic esters. This combination results in a fast-curing, versatile coating that can be applied in a variety of environments. Polyaspartic coatings are often used as a topcoat in flooring systems, particularly in environments that require a robust and long-lasting finish.

Unlike traditional epoxy coatings, polyaspartic acid offers rapid curing times, allowing for applications to be completed quickly and efficiently. This characteristic is particularly beneficial in industrial settings where minimizing downtime is a priority. Additionally, polyaspartic acid coatings can be applied in a wide temperature range, making them suitable for various environmental conditions.

Key Benefits of Polyaspartic Acid Coatings

1. Enhanced Durability One of the most significant advantages of polyaspartic acid coatings is their exceptional durability. These coatings are highly resistant to abrasion, chemicals, UV radiation, and moisture, ensuring long-lasting protection for surfaces in harsh environments. This quality makes them an attractive option for industries such as automotive and manufacturing, where equipment and surfaces are subject to wear and tear.

2. Fast Curing Polyaspartic acid coatings cure significantly faster than traditional epoxy and urethane coatings, often within hours. This rapid curing time means that projects can be completed in a fraction of the time, which is crucial for minimizing operational downtime. Businesses can return to normal operations almost immediately after application, enhancing overall productivity.

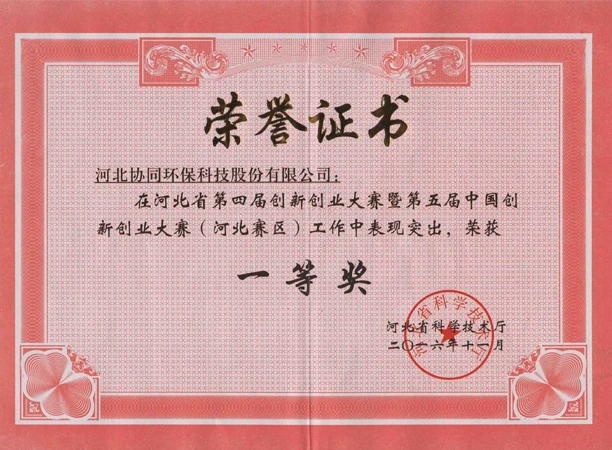

polyaspartic acid coatings manufacturer

3. Versatility The adaptability of polyaspartic acid coatings allows them to be used in a variety of applications. Whether it’s for flooring in commercial spaces, protective coatings for machinery, or finishes in automotive production, these coatings can be tailored to suit specific requirements. Available in different colors and finishes, they also allow for aesthetic customization.

4. Low VOC Emissions As environmental concerns continue to rise, the demand for eco-friendly coatings is increasing. Polyaspartic acid coatings typically have lower volatile organic compounds (VOC) compared to traditional options, making them a more sustainable choice. This attribute helps businesses adhere to environmental regulations and improve indoor air quality.

5. Resistance to Yellowing One of the common issues with many coatings is their tendency to yellow over time when exposed to sunlight. Polyaspartic acid coatings are designed to resist this phenomenon, ensuring that the aesthetics of coated surfaces remain intact even after prolonged exposure to UV light.

Applications in Various Industries

The versatility and performance of polyaspartic acid coatings enable their adoption across numerous industries. In the construction sector, they are widely used to enhance the longevity of concrete surfaces, driveways, and warehouses. The automotive industry benefits from their robust protection against chemicals, abrasions, and weathering, making them suitable for both exterior and interior applications. Additionally, manufacturing facilities utilize these coatings to protect machinery and equipment, reducing maintenance costs and extending the lifespan of their assets.

Conclusion

In conclusion, polyaspartic acid coatings represent a significant advancement in coating technology, offering a multitude of benefits that cater to the needs of various industries. Their durability, rapid curing, versatility, and eco-friendliness position them as a preferred choice when it comes to protective coatings. As the demand for high-performance coatings continues to grow, manufacturers of polyaspartic acid coatings are poised for an exciting future, contributing to enhanced operational efficiency and sustainability in various sectors. The evolution of these coatings illustrates the critical role that innovative materials play in shaping the future of industrial applications.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025