News

Sep . 25, 2024 17:48 Back to list

potassium of polyaspartic acid supplier

Understanding the Role of Potassium in Polyaspartic Acid Applications

Polyaspartic acid is a versatile polymer derived from the amino acid aspartic acid, commonly used in various industries ranging from coatings and adhesives to agricultural applications. One critical aspect of enhancing the performance of polyaspartic acid is the inclusion of potassium—a mineral that significantly influences the properties and functionality of these compounds. In this article, we will delve into the importance of potassium in polyaspartic acid formulations, its sourcing from reliable suppliers, and its overall impact across various industries.

The Importance of Potassium in Polyaspartic Acid

Potassium, as a vital nutrient and chemical component, plays several roles in the chemistry of polyaspartic acid. First and foremost, it acts as a vital ion that regulates osmotic pressure and fluid balance in plant and animal systems. In agricultural applications, potassium-modified polyaspartic acid enhances nutrient uptake efficiency, acting as a chelating agent. This means that it binds to essential nutrients, making them more available for absorption by plants, thus promoting healthier growth.

Additionally, in formulations aimed at improving the mechanical properties of materials, potassium improves the thermal stability and flexibility of polyaspartic coatings. These enhancements are crucial when it comes to protecting surfaces from environmental degradation or wear and tear. The inclusion of potassium in polyaspartic coatings can also aid in curing processes, leading to faster drying times and more durable finishes.

Sourcing Potassium from Reliable Suppliers

The quality and consistency of potassium used in polyaspartic acid formulations are of utmost importance

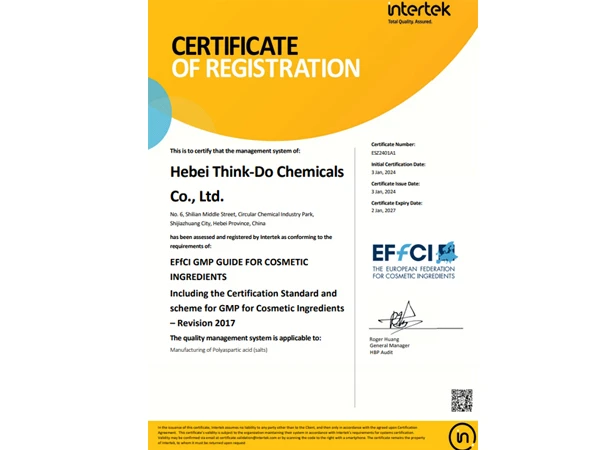

. Companies seeking to incorporate potassium must source it from reputable suppliers who offer high-purity and well-characterized products. Reliable suppliers not only provide essential product information but also comply with quality standards and regulations.potassium of polyaspartic acid supplier

When evaluating suppliers, several factors should be considered. These include the origin of the potassium, whether it is sourced naturally or synthetically, and the supplier's reputation in the industry. Additionally, inherent characteristics such as solubility and reactivity should be analyzed to ensure compatibility with specific polyaspartic acid formulations.

Adopting a stringent supplier selection process helps businesses avoid using inferior components that may compromise the quality and performance of their end products. This is particularly crucial for industries where product reliability and safety are paramount, such as construction and food production.

The Impact Across Various Industries

The use of potassium-enhanced polyaspartic acid spans a wide range of industries. In the construction sector, these polymers are widely utilized in high-performance coatings that offer excellent adhesion, chemical resistance, and weather durability. The inclusion of potassium not only improves the application properties of these coatings but also contributes to longer-lasting finishes, reducing maintenance costs over time.

In agriculture, potassium-enriched polyaspartic formulations are increasingly gaining attention as a means to improve soil nutrient management. These products can significantly enhance the efficiency of fertilizers, leading to increased crop yields and sustainable agricultural practices. Furthermore, the chelating properties of potassium polyaspartic acid can help mitigate soil salinity issues, which are a growing concern for farmers worldwide.

Conclusion

In conclusion, the synergistic relationship between potassium and polyaspartic acid cannot be understated. The mineral enhances the functionality and durability of polyaspartic formulations across various applications, from coatings in construction to nutrient management in agriculture. By partnering with reputable potassium suppliers, industries can ensure they are using high-quality elements that contribute to the efficiency and performance of their products. As market demands and environmental considerations evolve, the role of potassium in enhancing polyaspartic in various industries will likely continue to grow, enabling innovations that meet the needs of a changing world.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025