News

Sep . 06, 2024 10:58 Back to list

Calcium Sulfate Binder Retarder - Enhance Your Construction Materials

The Role of Retarders in Calcium Sulfate Binder Applications

Calcium sulfate binders, commonly known as gypsum-based materials, play a crucial role in construction and various industrial applications. Their effectiveness is often enhanced through the incorporation of retarders, substances specifically designed to delay the setting time of these materials. The use of retarders is increasingly being recognized as essential for ensuring workability, improving finishing, and enhancing overall performance.

The Role of Retarders in Calcium Sulfate Binder Applications

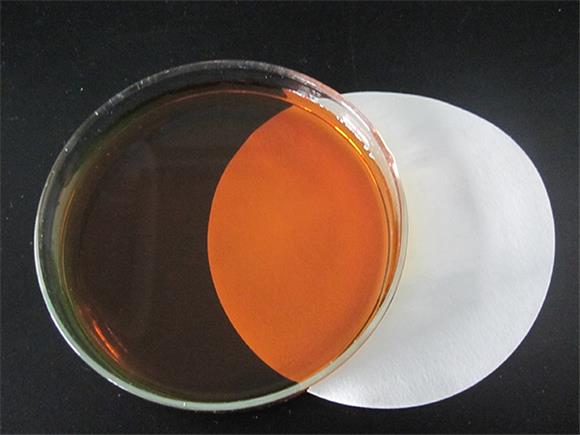

The selection of an appropriate retarder is critical as different retarders will interact variably with the gypsum binder. Common retarding agents include substances such as citric acid, sugars, and various organic compounds. Each type of retarder offers unique properties that can be tailored to various environmental conditions and specific applications. For instance, citric acid is widely used due to its effectiveness at low concentrations, providing prolonged workability without compromising final strength or adhesion.

retarder for calcium sulfate binder quotes

Moreover, industry professionals often seek quotes from suppliers regarding the costs and availability of various retarders. The market for retarders is notable; it features a range of products that meet diverse performance specifications. When procuring retarders, it is essential to consider not just the price but also the performance characteristics and compatibility with existing calcium sulfate formulations. Suppliers often provide detailed technical data sheets that can guide users in selecting the most appropriate product for their needs.

The importance of retarders is emphasized in large-scale projects where timing can significantly impact productivity and quality. In contexts such as plastering, flooring installation, or intricate mold applications, a small delay in setting time can lead to improved finish quality, reduced waste, and lowered overall costs. As construction techniques evolve and the demand for high-performance materials increases, the role of retarders in calcium sulfate applications becomes ever more significant.

In conclusion, the integration of retarders into calcium sulfate binder systems is a key factor in achieving desired performance outcomes. As professionals in the construction and manufacturing industries continue to pursue innovations and improvements, understanding the interactions between binders and retarders will remain crucial. As engagement with suppliers for quotes and performance specifications increases, the collaboration between material scientists and applicators will pave the way for enhanced applications of calcium sulfate binders across various sectors.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025