News

Sep . 15, 2024 01:20 Back to list

sodium polyaspartate nmr manufacturer

Understanding Sodium Polyaspartate A Focus on NMR and Manufacturer Quality

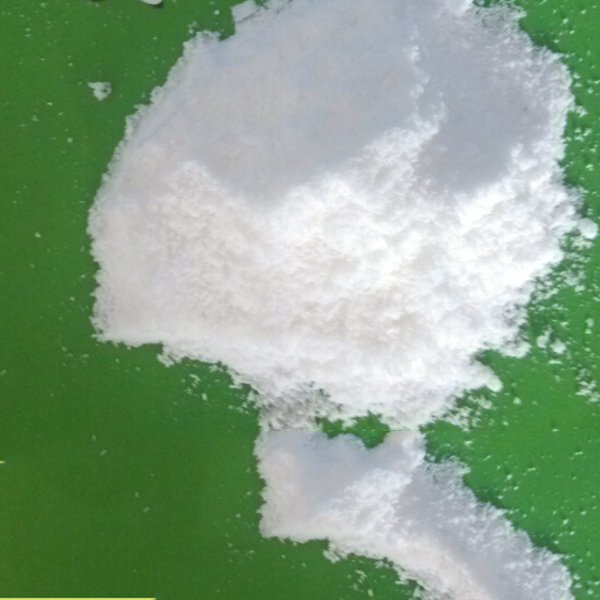

Sodium polyaspartate, a biodegradable polymer, has gained significant attention across various industries due to its unique properties and applications. Derived from the amino acid aspartic acid, this polymer is not only environmentally friendly but also exhibits excellent performance in water treatment, agriculture, and cosmetics. As the demand for sodium polyaspartate increases, manufacturers are focusing on enhancing product quality and performance, often utilizing advanced analytical techniques like Nuclear Magnetic Resonance (NMR) spectroscopy.

NMR spectroscopy is a powerful analytical tool used to determine the molecular structure of compounds. For sodium polyaspartate manufacturers, NMR provides critical insights into the polymer's composition, molecular weight, and structural properties. By analyzing the chemical shifts and spin interactions of hydrogen and carbon atoms in the polymer chain, manufacturers can confirm the synthesis process and assess the purity of their products.

One of the key advantages of using NMR in the production of sodium polyaspartate is its ability to offer non-destructive evaluation. This means that manufacturers can analyze the polymer without altering its physical or chemical properties, which is essential for maintaining product integrity. NMR can identify variations that may arise during production, enabling manufacturers to make necessary adjustments in real time, thereby ensuring consistent quality throughout the batch.

sodium polyaspartate nmr manufacturer

Additionally, understanding the molecular structure of sodium polyaspartate through NMR can help manufacturers tailor the polymer for specific applications. For instance, variations in molecular weight and chain length can affect the water solubility and biodegradability of the polymer, influencing its effectiveness in various settings. By fine-tuning these parameters, manufacturers can create specialized formulations that meet the diverse needs of their clients, whether in agriculture as a soil conditioner or in water treatment as a dispersant.

In selecting a manufacturer for sodium polyaspartate, it is crucial to ensure that they utilize advanced analytical methods, including NMR, to ensure the highest product quality. Reliable manufacturers often list their quality control measures, showcasing their commitment to maintaining stringent production standards. By choosing a manufacturer that prioritizes quality and employs NMR alongside other analytical techniques, customers can have confidence in the performance and safety of sodium polyaspartate.

The future of sodium polyaspartate looks promising as industries continue to seek sustainable alternatives to conventional synthetic agents. With manufacturers leveraging NMR spectroscopy for quality assurance, the development of high-performance, eco-friendly products will likely increase. As awareness of environmental issues grows, the role of polymer scientists and manufacturers will be pivotal in advancing the use of sodium polyaspartate and other biodegradable materials.

In conclusion, sodium polyaspartate represents a key innovation in sustainable materials, and the application of NMR by manufacturers plays a critical role in ensuring product quality. As this polymer gains traction in various sectors, ongoing research and refinement through advanced analytical techniques will be essential to meet the evolving demands of the market while preserving ecological integrity.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025