News

nov . 16, 2024 15:15 Back to list

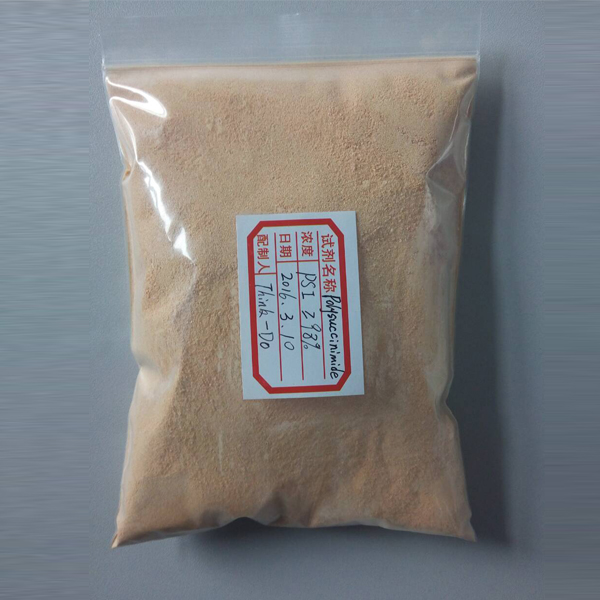

amino acid polymer factory

The Amino Acid Polymer Factory A Leap into Sustainable Biotechnology

In the landscape of modern biotechnology, amino acid polymers have emerged as a pivotal component in various industries, from medicine to materials science. The significance of amino acids— the building blocks of proteins—cannot be overstated. With the increasing demand for sustainable and biodegradable materials, amino acid polymers represent a promising solution that aligns with environmental sustainability goals. This article delves into the operations, benefits, and future prospects of an amino acid polymer factory.

Understanding Amino Acid Polymers

Amino acid polymers, or polyamino acids, are long-chain molecules formed by the polymerization of amino acids. These polymers possess unique properties, including biocompatibility, biodegradability, and the ability to be tailored for specific applications. Their amphiphilic nature—having both hydrophilic and hydrophobic segments—enables them to form micelles or other structures useful in drug delivery systems, making them valuable in pharmaceuticals. Moreover, when compared to conventional petroleum-based polymers, amino acid polymers offer a more eco-friendly alternative, aligning with the global shift towards sustainable manufacturing practices.

The Role of an Amino Acid Polymer Factory

Establishing an amino acid polymer factory involves a series of sophisticated processes that convert natural amino acids, often sourced from plant materials, into versatile polymers

. The factory typically consists of several units dedicated to different stages of production sourcing, polymerization, blending, and quality control.1. Sourcing The process begins with sourcing high-quality amino acids, which may include both essential and non-essential types. Sustainable sourcing is paramount; many factories prioritize agricultural by-products or waste from the food industry, thus minimizing waste while promoting circular economy principles.

2. Polymerization The heart of the factory lies in the polymerization unit. Here, amino acids undergo condensation or step-growth polymerization at controlled temperatures and pressures, resulting in the formation of polymers. Advanced techniques, like enzymatic polymerization, are increasingly employed to enhance yield and reduce energy consumption.

3. Blending and Formulation Post-polymerization, the produced polyamino acids are often blended with other biopolymers or functional additives to improve their properties, such as mechanical strength, thermal stability, or hydrophilicity. Tailoring these properties is essential for meeting specific industry standards.

amino acid polymer factory

4. Quality Control Ensuring the polymers meet rigorous quality standards is crucial. This involves rigorous testing for purity, molecular weight, and mechanical properties. A dedicated quality control unit develops protocols for ensuring that the end products are not only safe but also effective in their intended applications.

Environmental and Economic Benefits

The establishment of amino acid polymer factories has substantial environmental and economic benefits. Biodegradability of amino acid polymers contributes to reducing plastic waste, one of the most pressing ecological crises of our time. Unlike conventional plastics, amino acid-based materials break down naturally, which prevents accumulation in landfills and oceans.

Economically, the amino acid polymer industry is poised to grow significantly. By investing in this sector, businesses can tap into the growing demand for green materials, thus gaining a competitive edge. Furthermore, as traditional petroleum resources become increasingly scarce, transitioning to bio-sourced materials is not only wise but necessary for long-term sustainability.

Future Prospects

The future of amino acid polymers looks promising. Research and development are key to unlocking new applications, such as smart materials and advanced drug delivery systems. Collaborations between academia and industry will play a crucial role in innovating processes and discovering new types of amino acid polymers. The potential for scaling up production while lowering costs also remains a focal point for future endeavors.

Moreover, the factory itself may evolve with advancements in technology, possibly implementing automation and AI to optimize production processes. These innovations could enhance efficiency and further minimize the environmental footprint of manufacturing.

Conclusion

As we continue to confront the challenges posed by climate change and plastic pollution, the importance of amino acid polymers becomes increasingly evident. An amino acid polymer factory is not merely a manufacturing facility; it represents a commitment to sustainable development and the advancement of biotechnology. With the right investments and innovations, the future of amino acid polymers holds the promise of a greener, more sustainable world. Through these efforts, we can harness the power of nature’s own building blocks to create materials that are not only functional but also gentle on the planet.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025